- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- Home

- :

- モデルベース・デザイン・ツールボックス(MBDT)

- :

- モデルベース・デザイン・ツールボックス(MBDT)

- :

- Re: BLDC Motor Control with Model Based Design

BLDC Motor Control with Model Based Design

- RSS フィードを購読する

- トピックを新着としてマーク

- トピックを既読としてマーク

- このトピックを現在のユーザーにフロートします

- ブックマーク

- 購読

- ミュート

- 印刷用ページ

BLDC Motor Control with Model Based Design

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

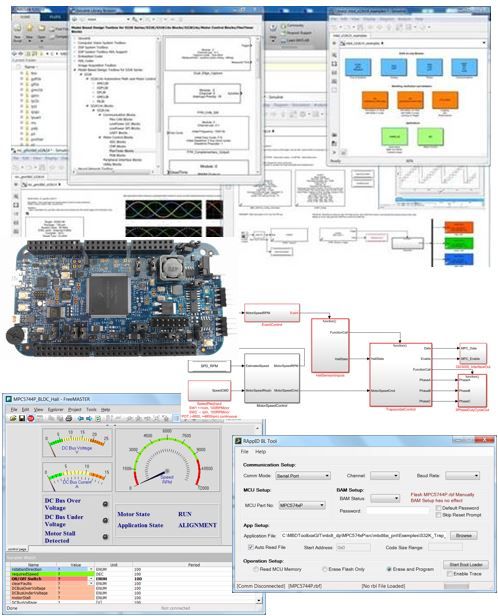

This course explains how to design and prototype a Motor Control Application using Model Based Design Toolbox for MPC5744P

Course Objectives

1 - Leverage MBD Toolbox Capabilities: Automatic C-code generation for different microprocessors Initialization and control for multiple peripherals Ease of use and speed of development for complex apps 2 - Highlight MPC5744P Capabilities For Industrial Control 3 - Learn Step-by-Step How To Control A Motor Speed: Sensors reading via GPIO Field Oriented Control of BLDC motors Pulse Width Modulation via FTM 4 - Understand How To Use Available Tools: FreeMASTER - real time data visualizer RAppID Bootloader Run-Time Debugging Tools |

This Course Explains:

- All the concepts and dependencies with the assumption that users meet first time with NXP products.

- Programming model of various peripherals, communication protocols or motor control concepts

- How to use Model Based Design to program a fairly complex application for Motor Control

MPC5744P and MotorGD DevKits unboxing MBD Toolbox environment setup

Video #2 – Application Partitioning Motor Control block diagram SW blocks and HW peripherals mapping

Video #3 – Configure Input Commands ADC configuration GPIOs configuration FreeMASTER interface What it is and where to use it How it works with digital controller Hall sensors setup GPIO and eTimer input capture Decode rotor initial position FOC sector identification 6-step commutation SVM procedure | Video #7 – Commutation Algorithm Validation 6-step commutation algorithm implementation SIL and PIL model conversion Validate results with MIL, SIL and PIL Video #8 – Power Stage Configuration MotorGD pin assignment PWM generation and validation FET pre-driver programming via SPI Power stage verification Video #9 – Open Loop Control System Open Loop control algorithm implementation Phase voltage commutation based on Hall sensors Spin BLDC motor for the 1st time Speed estimator implementation Testing and validation on real motor Video #11 – Closed Loop Control System PI Speed Controller tuning Closed Loop System transfer function Root Locus vs. Ziegler Nichols methods Video #12 – Motor Control System Final motor control Simulink model FreeMASTER control panel Tests and Conclusions |

What Is Available As Support Information For The Course:

| Video training | 19 videos showing step by step the theory, practical implementation and validation 145 minutes of video content |

| Training Material | PDF slides used for each lecture |

| Simulink Models | Matlab 2015b SLX models for each of the functionalities and peripherals covered in the lectures: ADC/GPIO/CAN/UART/FTM/SPI |

| Support | Any additional question will be answered via Community |

UPDATE August 2nd, 2019: Here is an interesting investigation on various controllers design/implementation/test made by andreicador13@gmail.com : https://community.nxp.com/thread/509234

- タグ:

- bldc example

- bldc motor control

- closed loop bldc motor control

- closed loop speed control example

- hall sensor commutation

- how to motor control

- model based design

- motor control

- motor control and drive

- motor control class

- motor control desing with model based design toolbox

- motor control example

- motor control example on mpc5744p

- motor control theory

- motor control training

- open loop control system

- pil

- pil verification

- pwm

- root locus

- sil

- simulink code generation

- speed controller

- speed estimator

- spi

- what is motor control

- ziegler nichols

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

hello,

These courses are very helpful for studying, thank you very much,

If the video can have subtitles, it is more helpful for studying.

best regards

hao

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

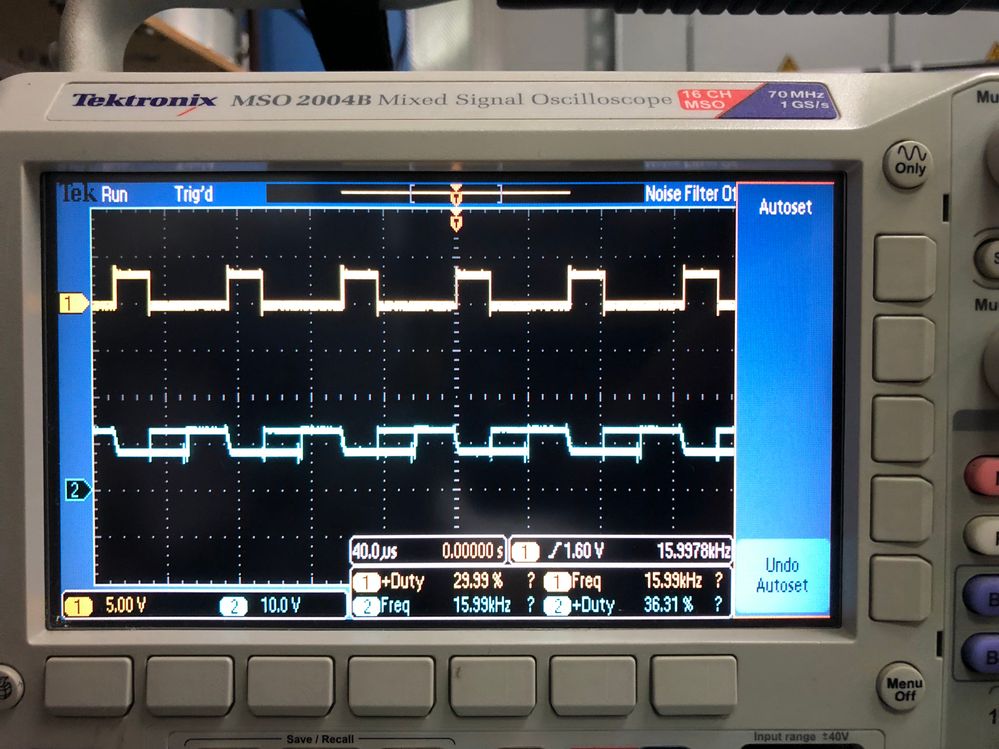

I added an SPI command to set the dead time of the GD3000 to 0 in the state machine. Test the waveform of phase A and GND, and the waveform shown below appears.The dead zone is 0 for a while and 24us for a while....

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

I think you need to use source insight to search all of the dead time variables in your project.

So that you can make clear where you should modify exactly.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

hello,

Thank you very much,I have solved my previous problem, but I have encountered a new problem.I want to use freemaster to connect my MPC5744 DevKit via CAN. But there is a problem like the one shown.

PS: 1. I have completed the repair of hot fix_8.

2. I use openSDA to connect freemaster to MPC5744 DevKit is normal.

thanks very much and wait for your reply!

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Zhang,

Your problem is similar with my previous one.

This kind problem maybe caused by:

Firstly, The corresponding NXP demo software project for MPC5744 dismatch with your board.

Sometimes, the NXP demo board use external/internal oscillar but the demo software use internal/external oscillar.

Secondly, we suggest you to pay your attention to the jumpers configuration for different connection cables. You need to read your demo board manual carefully. NXP board mainly have several connection methods including SCI, USB2UART, PEMicro, and openBDM.

All above connections have different jumper configurations.

So, please read the corresponding document carefully to make sure your jumers' configuration are exact.

.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

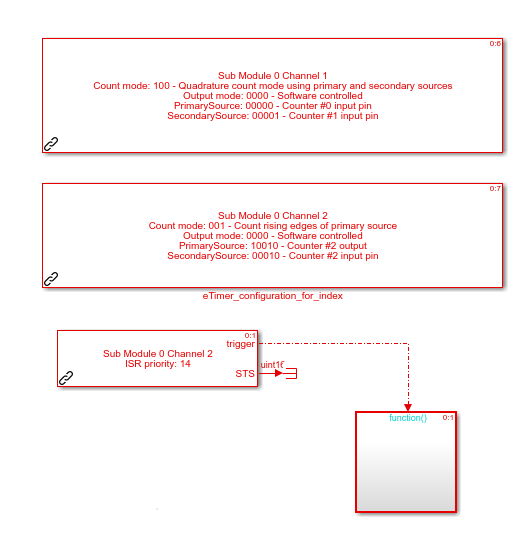

Hi,thomson

thanks for your help. I tried to use the etimer module of MBDT for MPC574XP to read the signal of the photoelectric encoder. I can get the count value of a certain etimer module, but I can't make the etimer module detect the pulse of the encoder index and then clear the value of the register captured by etimer. How can I do this?

PS, I used two etimer modules and one used for orthogonal decoding. Read the pulses of the A and B phases of the encoder. Another pulse is used to detect the index and generate an interrupt.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Dear Zhang,

Sorry to reply too late. I was on my business tour in last two weeks. I saw your problem. My answer is you can add a detection fucntion manually in the generated code. Or you can add one user define simulink function in your BLDC module.

To detect the first and the second pulses, you need to be very familar with your NXP TIMERS, which is used for PWM signal detecting.

To NXP MCU, it is much easier for PWM signal detecting. After read the MCU manual, you can find the timer exact registers description for the hex value of the registers.

Usually, if you use pulse A and pulse B then you need to use one timer with two channels to detect the first clock time and the second clock time for your machine. After you get the two hex values you can evaluate the exact time, frequency and periods or any variable you want.

The problem is you need to reset your clock before start your function because all of the clock counting need to start from zero clock time.

Good Luck!

Thomson

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hello,

can you tell me how to set the deatime of MC34GD30000?use the MBDT simulink.I used your routine to find that the actual dead time is 24us, which is obviously too long.

thank you very much and wait for your reply

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

When you generate the model from simulink model to C code, you can locate the exact location of GDU part settings.

Locate the exact deadtime register, and then modify the deadtime value from 24us to 1us.

So often we use 1us to make BLDC/PMSM rotate as faster as possible.

To make clear which register is the deadtime register, please research the corresponding MCU manual.

You can download the corresponding manual from www.nxp.com

GOOD LUCK!

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi,I want to know how to use the MBDT for MPC5744P to read the conversion value of the ADC through DMA. I tried to use your routine and found that I can't read the conversion value of the ADC at the destination address.Can you provide a demo for reference.

thank you very much and wait for your reply

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hello,

MPC5744P should have its own demo code. Or you can use MBDT simulink modues of BLDC or FOC to make your motor rotate. Since the MCU model can be changed from one to another, you can change it the simulink MCU model from MC9S12 to MPC5744P and then generate your code directly.

If you use the exact evaluation board, you can make your motor rotate immediately.

:smileyhappy:

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Daniel,

I very excited to find the "Motor Control Class",and i congratulate with you achiving complete success in advance.if yes,i wanna join in.and now i am learning the PMSM control,Can you add some videos about the PMSM control likely the BLDC?

Best Regrads!

Eden Li

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Eden Li,

We start with BLDC because is simple. Depending on the feedback we get - for sure we can think of another course on FOC Sensorless on PMSM - for second half of this year.

Best regards,

Daniel

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Daniel,

For the BLDC MCT toolbox model toolbox 1.3 , the target MCU does not contain the target MCU: MC9S12ZVML32. I have no idea why NXP does not provide the both options for both MC9S12ZVML32 and MC9S12ZVM32.

What is the differences between MC9S12ZVML32 and MC9S12ZVM32?

How can we reuse the model for MC9S12ZVML32?

Do you have any better suggestions for MC9S12ZVML32? Or do you have example BLDC modles for MC9S12ZVML32 ?

Thomson

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Thomson,

This toolbox has been release some time ago and in the meantime was not updated to support all the available derivatives. Anyhow - the parts you are refering looks very similar - please check table 1 in this application node

https://www.nxp.com/docs/en/application-note/AN5330.pdf

You may reuse the MATLAB support for MC9S12ZVM32 to develop applications for MC9S12ZVML32 and should work fine.

As a BLDC example you can start with this one: Example Model: S12ZVM Trapezoidal Motor Control and migrate it to use the MC9S12ZVM32.

Hope this helps!

Daniel

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Daniel,

I downloaded the BLDC model you attached, however, I found when I use a simulink scope model, which contains 3

three input ports, connected to the corresponding 3 BLDC motor PWM output ports( pwma , pwmb and pwmc) , with

matlab BLDC data file ?.mat putted in matlab enviroment, the BLDC PWM output signals are always zero. It means the

BLDC model you attached did not run at all.

How can I make this BLDC simulink model generate the exact PWM signal waves when I attached a simulink scope?

Or this simulink model need to be actived to run with free master project, which attached in the simulink model file?

If yes, please let me know the corresponding pdf, http links or other resources with details how to make this simulink

BLDC model generate exact right PWM output signal.

Finally, I downloaded the FOC simulink model in your class, however, it always generate zero in the simulink scope,

which means the FOC motor does not run at all.

I have no idea, how to make this models generate exactly right signal output?

Thank you very much and wait for your reply.

Thomson

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Thank you very much. This helps.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Daniel,

the course is a great idea! I will join it for sure. At my company we are using MBD and we are generating code for NXP processors but we don't use MBD toolbox or any other board support packages.

A few months ago we were evaluating MBD toolbox using a few low-cost devkits from NXP (for: MC9S12ZVMx, MPC5643L and Kinetis). And we have had multiple problems/questions like: compiler version settings, Rappid Bootloader usage, specific block usage etc. Even questions about intended usage/application of MBD toolbox itself.

The most important thing (at least for us) would be to have alive and responsive channel (like this forum) with direct response from MBD toolbox people at NXP.

I can't also see MotorGD DevKit available anywhere. Can You point us what exactly is the course hardware setup ?

It looks like DEVKIT-MPC5744P with DEVKIT-MOTORGD and some BLDC motor (but what model exactly) - but there is no info about this kits on the NXP site ?! Are they available now (and where) ?

Best regards

Maciek

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Maciek,

We look forward to answer all your questions. We want to change the way we do things and become much more involved with the customers/users of MBD via this community and this course is one of the first initiatives that hopes to clarify some of the aspects you have already highlighted.

For the setup - please wait until Monday when we will release the 1st video - mainly that is the content of the Introduction video - unboxing the devkits and various information about it. We want to avoid spoiler alert at this time :-)

Thank you!

Daniel

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hello Daniel,

The course sounds very interesting and I have some questions. It is necessary to sign up for the course? Will it be possible to view the videos after the release week appointments? Unfortunately, I will not be able to participare during the first three weeks of the course. Is it necessary to have the MotorGD DevKit to participate? What IDE will be used for the course, the S32 or is it possible to work with code warrior?

Greetings,

John