- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- Home

- :

- i.MX Processors

- :

- i.MX Processors Knowledge Base

- :

- i.MX 6/7 DDR Stress Test Tool

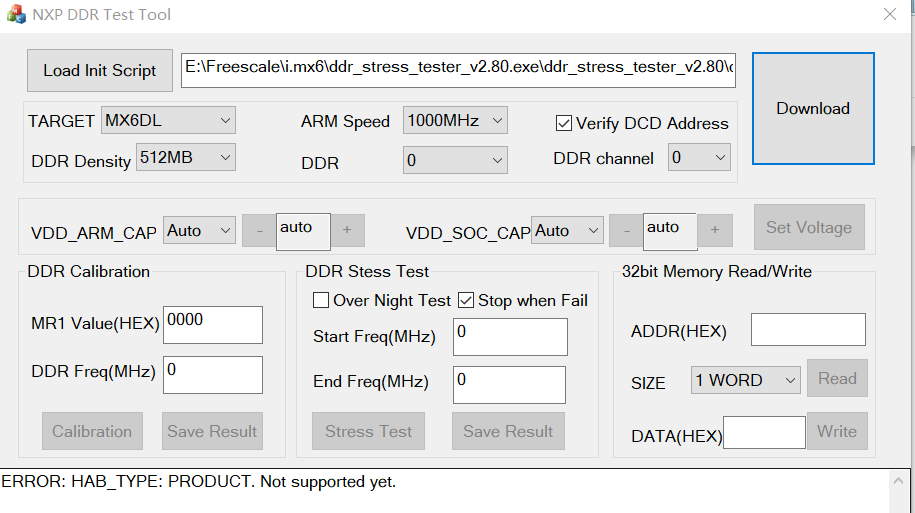

i.MX 6/7 DDR Stress Test Tool

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

i.MX 6/7 DDR Stress Test Tool

i.MX 6/7 DDR Stress Test Tool

Important: If you have any questions or would like to report any issues with the DDR tools or supporting documents please create a support ticket in the i.MX community. Please note that any private messages or direct emails are not monitored and will not receive a response.

i.MX 6/7 Family DDR Stress Test

The i.MX6/7 DDR Stress Test Tool is a PC-based software to fine-tune DDR parameters and verify the DDR performance on a non-OS, single-task environment(it is a light-weight test tool to test DDR performance). It performs write leveling, DQS gating and read/write delay calibration features.

The tool described on this page cover the following i.MX 6/7 series SoCs:

- i.MX 6DQP (Dual/Quad Plus)

- i.MX 6DQ (Dual/Quad)

- i.MX 6DL/S (Dual Lite/Solo)

- i.MX 6SoloX

- i.MX 6SL

- i.MX 6SLL

- i.MX 6UL

- i.MX 6ULL/ULZ

- i.MX 7D/S

- i.MX 7ULP

Note that the DDR Stress test tool supports the all of the above i.MX SoCs, however, some of the supported i.MX SoCs named in the tool support multiple i.MX SoCs as follows:

- MX6DQ – when selected, this supports both i.MX 6DQ and i.MX 6DQP (Plus)

- MX6DL – when selected, this supports both i.MX 6DL and i.MX 6S (i.MX 6DLS family)

- MX6ULL – when selected, this supports both i.MX 6ULL and i.MX6 ULZ

- MX7D – when selected, this supports both i.MX 7D and i.MX 7S

The purpose of the i.MX 6/7 series DDR Tools is to enable users to generate and test a custom DRAM initialization based on their device configuration (density, number of chip selects, etc.) and board layout (data bus bit swizzling, etc.). This process equips the user to then proceed with the bring-up of a boot loader and an OS. Once the OS is brought up, it is recommended to run an OS-based memory test (like Linux memtester) to further verify and test the DDR memory interface.

The i.MX 6/7 series DDR Tools consist of:

- DDR Register Programming Aid (RPA): i.MX 6/7 Series DDR Tool Release

- DDR Stress test: Described below

There are three options to run the DDR Stress test. Each of these options are provided in the attached zip files. The following is a high-level overview of each option along with the naming convention of the associated zip file:

Option 1 GUI based:

Run the GUI executable and connect your board to the host PC via USB

- Archive file: ddr_stress_tester_vX.xx.zip

- The tool will first need to run a DDR initialization script for the specified i.MX SoC (refer to Load Init Script in the GUI tool). Example initialization scripts based on NXP's development boards can be found in this zip file under the script folder. Note, these scripts may need to be modified for your custom board and memory.

Option 2 DDR Stress Tester: JTAG Interface

A hardware debugger connected to the board via the JTAG interface is used to download an elf file into the i.MX SoC OCRAM (internal RAM) and then begin execution. Results are shown on the UART serial port (115200-8-n-1).

- Archive file: ddr_stress_tester_jtag_vX.xx.zip

- As with the GUI tool, the JTAG/debugger option will first need to run a DDR initialization script for the specified i.MX SoC. Refer to the GUI tool description above for the location of the example scripts (which are found in the ddr_stress_tester_vX.xx.zip file).

- Note that the scripts are available either in the RealView ICE format (.inc file) or the DS-5 DSTERAM format (.ds). For other debuggers, the user will have to modify the script's command syntax for their specific debugger. This is also true if converting from a RealView Ice (.inc) format to a DS-5 DSTREAM (.ds) format and vice versa.

- The DDR Stress Tester executable (starting with V2.20) has an auto UART detection feature. If a different UART port for the serial console has been chosen than used on the NXP development tool (EVK, SABRE) specific commands can be added to the DDR initialization script that allows you to configure for the specific UART and then load and run the elf executable. Refer to the FAQ section of this community post and the txt file found in the JTAG archive file for instructions.

Option 3 U-Boot:

The boot loader u-boot is running and commands in u-boot are used to download the bin file into SoC OCRAM and begin execution. Results are shown on the UART serial port (115200-8-n-1)

- Archive file: ddr_stress_tester_uboot_vX.xx.zip

- When downloading the DDR Stress Test Tool by u-boot, please copy the ddr-test-uboot-jtag-mxxxx.bin to SD card and load it to IRAM using the 'fatload' u-boot command (see notes below when using newer versions of u-boot). For i.MX6, please load the binary to 0x00907000. For i.MX7D, please load the binary to 0x00910000. It is imperative to first disable the I and D cache in u-boot as shown below as the DDR Stress Test re-configures and re-enables the cache and MMU page table.

While this option allows the user to load and run the DDR stress test from u-boot, NXP highly recommends executing the GUI based version for system testing and debugging. The u-boot version is considered a “last resort” for systems in production which may not have USB or JTAG connectivity. The reasons behind this stance are:

- In the GUI version, the system starts “clean” and uninitialized, whereas u-boot initializes many SoC features outside the knowledge of the DDR stress test and may conflict with the stress test operation

- When running the u-boot version, the test will overwrite the contents of u-boot residing in DDR, hence the test will overwrite any data in DDR. Once the stress test is loaded and executed, u-boot itself will no longer be accessible. To return to the functionality of u-boot, a system re-boot is required.

Newer versions on u-boot do not allow a direct loading of the DDR stress test code from the SD card (boot media) directly to the SoC internal OCRAM (aka IRAM). Hence, the procedure is updated to first load the DDR stress test code into DDR and then copy into OCRAM, as shown in the procedure below:

u-boot> dcache off;icache off;fatload mmc 2:1 0x12000000 ddr-test-uboot-jtag-mx6dq.bin;cp.b 0x12000000 0x00907000 0x20000;go 0x00907000

As u-boot initializes many peripherals that may conflict with the operation of the DDR stress test, it is necessary to clock gate these peripherals prior to running the DDR stress test. Hence, it is highly recommended to augment the procedure above as follows:

u-boot> dcache off;icache off;fatload mmc 2:1 0x12000000 ddr-test-uboot-jtag-mx6dq.bin;cp.b 0x12000000 0x00907000 0x20000;

u-boot> mw 0x020c4068 0x00C0000F;

u-boot> mw 0x020c406c 0x00000000;

u-boot> mw 0x020c4074 0x3F300000;

u-boot> mw 0x020c4078 0x0000F300;

u-boot> mw 0x020c407c 0x0F000003;

u-boot> mw 0x020c4080 0x000003FC;

u-boot> go 0x00907000

Note, in the above procedure, it is recommended to write to each clock gate register in separate commands (refer to commands starting with “mw”). The SoC requires a finite amount of time to gate each clock hence performing this sequence with a new command line write ensures the SoC has time to gate the intended clocks.

| Stress Test Revision | Features | Comments |

|---|---|---|

| 3.00 |

Add i.MX 7ULP support in the GUI version |

Known issues: USB connection is unstable when under USB HUB or some PC environments |

| 2.92 |

Minor correction with write leveling calibration code error check to avoid a corner case of flagging an error when none have occurred. |

|

| 2.91 |

Resolved issue with write leveling calibration code where a race condition in the code may result in the calibration routine not being able to find any delay values. |

Only applies to MX6 series SoCs that support DDR3. |

| 2.90 |

Reserve write delay line register (MMDC_MPWRDLCTL) configuration as DDR script does when do write calibration. In previous releases, MMDC_MPWRDLCTL would be changed to 0x40404040 by default. |

* Further details available in the release notes

_________________________________________________________________________________________________________________________________________

FAQ

Q. I see an error message that states "ERROR: DCD addr is out of valid range.", why is this and how do I resolve?

A. Sometimes, when using the register programming aid, there are registers writes that are not supported in the DCD range. Try looking for the following items and comment them out from the DDR initialization script:

wait = on setmem /16 0x020bc000 = 0x30 // disable watchdog (note the address for this may be different between i.MX6x devices)

Q. How do I select the "DDR Density" pull-down menu and what is the purpose of this?

A. The DDR Density pull-down menu gives the user the option of testing a DDR density smaller than what they actually have on their board. The advantage of doing this is to speed up test time to allow the user to perform a "quick test" of their system. IMPORTANT: it is imperative that the user not set this value higher than the supported density on their board, doing so will cause the stress test to fail and/or lock up.

The DDR Density has a different meaning depending on the memory type being tested (DDR3 or LPDDR2):

For DDR3, this is the density per CHIP SELECT. So if your board has two chip selects, and each chip select has 512MB, you would simply select 512MB or lower. The default setting will simply set this to the detected density per chip select.

For LPDDR2, this is the density per CHANNEL. This is only relevant for MX6 devices that support 2 channel LPDDR2 memories (MX6DQ, MX6DL). For other MX6 devices that support only one LPDDR2 channel, then this is the total density (for the maximum setting) for that channel. Note that for LPDDR2, the number of chip selects (per channel) is irrelevant when selecting the density to test as the stress test combines both chip-selects into one combined density per channel. For example, lets say you have a 2GB LPDDR2 device, which 2 channels and 2 chip-selects per channel. That means you have 512MB per chip select, per channel. Or, it also means you have 1GB per channel when combining both chip selects per channel. In this case, you would choose (a maximum setting of) 1GB in the DDR Density drop down menu. However, this is also the same setting as the default setting (which you are welcome to still choose 1GB to convince yourself that 1GB per channel is indeed being tested).

Now let's assume you have only one channel (LPDDR2) and one chip select, with a density of 128MB; in this case, the maximum DDR Density you can select is 128MB.

Let's assume you have one channel and two chip selects, each chip select is 128MB; in this case, the maximum DDR Density you can select is 256MB (a combination of both chip selects).

Note, for the MX7D, an actual density needs to be entered. For the MX6x series, simply leaving this field as Default will cause the DDR stress test to ascertain the supported density from the DDR init script. As the MX7D DDR controller is different, this feature is not supported, hence it is required for the user to enter an actual density (for more details regarding MX7D usage of density and number of chip-selects, see the next FAQ on the DDR CS setting).

Q. What is the purpose of the "DDR CS" pull-down option?

A. The answer depends on which processor you are testing:

For the i.MX 6x series:

This pull down menu gives you the option of testing one chip select (CS0) or ALL (both) chip selects *IF* you have a two-chip select configuration. If you have a two-chip select configuration, then this allows you to test only one chip select for faster test time; else you can choose to test both chip selects. Note that if you have a one-chip select configuration and you choose "ALL", the stress test will return an error.

For the iMX 7D:

Because the MX7D DDR controller is different, the DDR stress test will need the user to supply the entire supported density found on their board. The chip select field should be left as is (0) as the test will naturally test one chip select to the next. For example, let’s assume you are using two chip selects, with each chip select being 512MB. In this case, you would enter 1GB for the DDR Density field ensuring that both chip selects will be tested. The user is allowed to enter a density less than the density found on their board (for quicker testing), but keeping in mind both chip selects may not be tested in this case.

Q. I run DDR calibration using the DDR Stress Test Tool to obtain the calibration results. Are these calibration parameters are written to the uboot flash_header.S automatically or manually?

A. The calibration values obtained from the DDR Stress Test Tool will need to be manually updated in the flash_header.S file or any other DDR initialization script.

Q. When running the DDR stress test on MX7D and I try to perform calibration, I get an error stating that calibration is not supported, is this expected?

A. Yes, calibration is not supported or needed when using MX7. The reason is, MX7 uses a different memory controller than the MX6 series. The MX6 series memory controller has built-in support for calibration where the MX7 memory controller does not.

Q. When running the GUI version of the DDR stress test, on MX7 and I leave DDR Density as default, I get an error in the tool stating I must supply a density. Why is this?

A. This is due to the fact that MX7 uses a different memory controller than the MX6 series. In the MX6 series, it was possible to calculate the memory density from the memory controller register settings. The MX7 memory controller is different and does not lend itself to easily calculate the supported density based on the register settings. Instead, the user should verify the density on their board and selected this value in the DDR Density pull-down menu.

Q. I noticed that when I run write-leveling calibration I sometimes see a note that due to the write-leveling calibration value being greater than 1/8 clock cycle that WALAT must be set to 1. What does this mean?

A. In the MMDC chapter of the reference manual for the specific i.MX 6 device, the need to set WALAT is described in the MDMISC register as follows:

"The purpose of WALAT is to add time delay at the end of a burst write operation to ensure that the JEDEC time specification for Write Post Amble Delay (tWPST) is met (DQS strobe is held low at the end of a write burst for > 30% a clock cycle before it is released). If the value of any of the WL_DL_ABS_OFFSETn register fields are greater than ‘1F’, WALAT should be set to ‘1’ (cycle additional delay). WALAT should be further increased for any full-cycle delays added by the WL_CYC_DELn register fields."

Therefore, if the write-leveling calibration routine detects any write-leveling delay value greater than 0x1F, it will note to the user that WALAT must be set and the user should update their DDR3 init script to ensure WALAT is set. Sometimes, a user may find that the write-leveling delay value may fluctuate from one run to the next, which is quite normal. If it is found that this delay is "borderline" meaning sometimes it is greater than 0x1F and sometimes it might be slightly less, then it is ok to go ahead and set WALAT permanently in your init script as there is no harm in doing so and will ensure you will stay within JEDEC's tWPST.

Q. I sometimes see that after running write-leveling calibration that delay values being reported back are zero'd out (0x00), and then at times I see a non-zero value being reported, why is this?

A. It is quite normal to see slight variations in the delay value between write-leveling calibration runs. The write-leveling calibration routine assumes a majority of users have designed their board such that the DDR3 memories are placed close to the i.MX 6 SoC. There’s a mechanism in NXP’s DDR Stress test write leveling calibration code that checks the returned write leveling value. If the write-leveling calibration routine detects that the returned delay value is greater than ¾ of a clock cycle, it will "zero out" the delay value. It does this because it assumes that such a large delay result is due to the fact that the DQS signal is already delayed relative to the SDCLK, and to align DQS with SDCLK requires the calibration routine to delay DQS even further to align it to the next SDCLK edge, something we ideally would like to avoid. JEDEC specs that the DQS edge must be within 25% of a SDCLK cycle with respect to the SDCLK edge, so having DQS initially slightly delayed from SDCLK is actually ok, hence why the calibration routine “zero’s” this out when the returned value exceeds ¾ of a clock cycle. In cases like this, the DQS edge and SDCLK edge are so close together that in some calibration runs, the DQS edge may slightly precede SDCLK (resulting in a very small write-leveling delay value) and other runs, it may be slightly delayed relative to the SDCLK (resulting in a very large write-leveling delay value that will try to align DQS to the next SDCLK edge, hence needs to be zero’d out).

Q. When using the JTAG version of the DDR stress test, how can I select a different UART port for my serial port?

A. Under the folder ddr_stress_tester_jtag_v2.52, there's a text file that describes how to add a different UART port by adding a few additional commands to your DDR init script. The following is an outline of these commands:

1. Ungate UART module clocks (most NXP scripts ungate all of the peripheral clocks at the beginning of the script, so this part is already done)

2. Configure the IOMUX options for the pins you wish the UART to use (normally an IOMUX option for UART_TX and UART_RX, and a daisy chain option for the UART_RX input)

3. Enable the desired UART module via the register UCR1, bit UART_EN

4. Disable other UART modules (UCR1[UART_EN] = 0). Normally disabling UART1 should be sufficient, but it doesn't hurt to disable all of the other un-used UART options for the purpose of the stress test.

Here's an example in the .ds file vernacular of a set up as follows: MX6DQ, UART4 on KEY_COL0 and KEY_ROW0 (assume clock is ungated to all peripherals):

mem set 0x020E01F8 32 0x00000004 #// config_pad_mode(KEY_COL0, ALT4) mem set 0x020E01FC 32 0x00000004 #// config_pad_mode(KEY_ROW0, ALT4); mem set 0x020E0938 32 0x00000001 #// Pad KEY_ROW0 is involved in Daisy Chain. mem set 0x02020080 32 0x00000000 #//disable UART1 in UART1_UCR1 (Note, you can disable other UART modules as well) mem set 0x021F0080 32 0x00000001 #//enable UART4 in UART4_UCR1

Here's another example in the .inc file vernacular of a set up as follows: MX6SX, UART5 on SD4_DATA4 abd SD4_DATA5 (assume clock is ungated to all peripherals):

setmem /32 0x020E0294 = 0x2 //IOMUXC_SW_MUX_CTL_PAD_SD4_DATA5, ALT2; UART5_TX_DATA setmem /32 0x020E0290 = 0x2 //IOMUXC_SW_MUX_CTL_PAD_SD4_DATA4, ALT2; UART5_RX_DATA setmem /32 0x020E0850 = 0x00000000 // IOMUXC_UART5_IPP_UART_RXD_MUX_SELECT_INPUT, daisy chain for UART5_RX input to use SD4_DATA4 setmem /32 0x021F4080 = 0x00000001 // Enable UART_EN in UCR1 of UART5 // Disable UART_EN in UCR1 of UART1, UART2, UART3, and UART4 setmem /32 0x02020080 = 0x00000000 // UART1 setmem /32 0x021F0080 = 0x00000000 // UART2 setmem /32 0x021EC080 = 0x00000000 // UART3 setmem /32 0x021E8080 = 0x00000000 // UART4

Related Resources Links:

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hi,

I'm using the I.MX6ULL_DDR3_Script_Aid_V0.01 init script and the ddr_stress_tester_v2.70 to perform calibration for the iMX6ULL SoC.

after calibration has finished,I recive 6 registers to update vlaues for:

MMDC registers updated from calibration

Write leveling calibration

MMDC_MPWLDECTRL0 ch0 (0x021b080c) = 0x00000000

MMDC_MPWLDECTRL1 ch0 (0x021b0810) = 0x00100010

Read DQS Gating calibration

MPDGCTRL0 PHY0 (0x021b083c) = 0x01380140

MPDGCTRL1 PHY0 (0x021b0840) = 0x00000000

Read calibration

MPRDDLCTL PHY0 (0x021b0848) = 0x40402A2A

Write calibration

MPWRDLCTL PHY0 (0x021b0850) = 0x40403E38

Success: DDR calibration completed!!!

the following 2 registers:

MMDC_MPWLDECTRL1 ch0 (0x021b0810) = 0x00100010

MPDGCTRL1 PHY0 (0x021b0840) = 0x00000000 (value is always 0)

do not appear in the I.MX6ULL_DDR3_Script_Aid_V0.01 init script nor do they appear in the register list

section "36.12 MMDC Memory Map/Register Definition" in the i.MX 6ULL Applications Processor Reference Manual,

and they do not appear also in NXP's board .cfg file:

http://git.freescale.com/git/cgit.cgi/imx/uboot-imx.git/tree/board/freescale/mx6ullevk/imximage.cfg?...

Reading their value in U-boot returns 0x0000000

are these registers part of the iMX6ULL calibration process or this is a bug of the tool?

I know they exist in other SoC but wanted to verify id they are not necessary and can be ignored

i've tried also v2.60 of the tool but result is the same

would appreciate your clarification,

Thanks,

Aviad

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hello Aviad,

6ULL only supports 16 bit bus width (Byte 0 and Byte 1). The registers you mentioned store the calibration values for write leveling and DQS gating for Byte 2 and Byte 3 - bytes that are used in wider bus widths (32 bit etc.) in other SoCs. So for 6ULL they have no meaning and the tool output is probably just an artefact when support for 6ULL was added in the tool and sources from previous SoCs were used.

OliverChen could you please arrange for an update of the tool?

Best Regards,

Jan

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hi @Jan_Spurek,

I'll update it in the next version.

B.R

Oliver

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

do we have the code for this 'ddr-test-uboot-jtag-mx6ul.bin", can you share it.

thanks

niranjan

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hello,

code sources are not provided, sorry.

Regards,

Yuri.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hi,

In the v2.70 tool the current maximum ARM SPEED supported for the iMX6ULL SoC is 700Mhz.

For the new iMX6ULL SoC revisions which now support of 900Mhz arm speed what is your recommendation for speed input?

Generally speaking, the 900Mhz SoC operates over a wide range of frequencies with the 900Mhz being only in certain scenarios but

typical speed being 528Mhz or even less what is the recommended ARM SPEED value for performing a calibration, should it be set to Maximum

speed or typical speed? does this have an effect on DDR calibration process and results since DDR controller speed is the same?

Will appreciate your response.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

We are working our custom board with iMX6 Quad processor. On trying the DDR3 calibration for 1GB with DDR Stress Tool V2.70 using GUI we are getting an error as: ERROR FOUND, we can't get suitable value !!!!

We have been working to resolve this for long time but unsuccessful.

thanks for the help in advance. The log is as below:

Density per chip select: 1024MB

============================================

Current Temperature: 35

============================================

DDR Freq: 396 MHz

ddr_mr1=0x00000004

Start write leveling calibration...

running Write level HW calibration

Write leveling calibration completed, update the following registers in your initialization script

MMDC_MPWLDECTRL0 ch0 (0x021b080c) = 0x00150017

MMDC_MPWLDECTRL1 ch0 (0x021b0810) = 0x001F0016

MMDC_MPWLDECTRL0 ch1 (0x021b480c) = 0x00150023

MMDC_MPWLDECTRL1 ch1 (0x021b4810) = 0x00080011

Write DQS delay result:

Write DQS0 delay: 23/256 CK

Write DQS1 delay: 21/256 CK

Write DQS2 delay: 22/256 CK

Write DQS3 delay: 31/256 CK

Write DQS4 delay: 35/256 CK

Write DQS5 delay: 21/256 CK

Write DQS6 delay: 17/256 CK

Write DQS7 delay: 8/256 CK

Starting DQS gating calibration

. HC_DEL=0x00000000 result[00]=0x11011111

. HC_DEL=0x00000001 result[01]=0x11011111

. HC_DEL=0x00000002 result[02]=0x01000010

. HC_DEL=0x00000003 result[03]=0x01000010

. HC_DEL=0x00000004 result[04]=0x11111111

. HC_DEL=0x00000005 result[05]=0x11111111

. HC_DEL=0x00000006 result[06]=0x11111111

. HC_DEL=0x00000007 result[07]=0x11111111

. HC_DEL=0x00000008 result[08]=0x11111111

. HC_DEL=0x00000009 result[09]=0x11111111

. HC_DEL=0x0000000A result[0A]=0x11111111

. HC_DEL=0x0000000B result[0B]=0x11111111

. HC_DEL=0x0000000C result[0C]=0x11111111

. HC_DEL=0x0000000D result[0D]=0x11111111

ERROR FOUND, we can't get suitable value !!!!

dram test fails for all values.

Error: failed during ddr calibration

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Calibration failed at byte1 and bye6, normally it is caused by HW issue.

Please check your HW design/soldering first.

Or ask local support team for help.

Please rise a new thread for this issue.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Thanks LinWang for the suggestion.

Can you please suggest any specific issue in the board? And how did you decode the issue is with byte 1 and byte 6?

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hello Pranav,

Please rise a new ticket for further discussion.

Thanks!

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hi nice tool.

I see it interesting for my production team to run on certain problematic board for the stress tool.

Would it be possible to have access to more memory setting in the script. Currently in my system it require to set a GPIO bit to 1. When my power management circuit do not see this bit raising in a couple of second it power-off the board.

I tried to set the IOMUX and GPIO in the script with setmem but without success as it do not fall under DCD address range.

setmem /32 0x020e02B4 = 0x00000005 //IOMUXC_SW_MUX_CTL_PAD_SD3_DAT4 GPIO7_01

setmem /32 0x0209C000 = 0x00000080 //GPIO7_1 IO 7 to 1

setmem /32 0x0209C004 = 0x00000080 //GPIO7_1 direction register (GPIO1_GDIR) IO 7 Output

It would be nice to be able to address some register acces in other range then the DCD in order to tweak some on board peripheral with gpio.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Dear Oliver,

is there a way to stop, finish or interrupt the "Over Night Test"? The Only way i figgured out so far is a power reset of my board. is there a nicer way?

regards

Hans

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

I use the DDR_Tester on my board use chip MCIMX6S5EVM10AC,but i get an error like the fllowing picture

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hi @oliver_chen,

One of the customers ask me if we can provide an older DDR tool (2.8 version), where can I find this?

Regards.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hello.

I'm currently running a stress test targeting MXULL.

Then, I get the following test results as logs, but I don't know what exactly each test is doing.

I would like to know.

t0.1: data is addr test

t0: memcpy11 SSN test

t1: memcpy8 SSN test

t2: byte-wise SSN test

t3: memcpy11 random pattern test

t4: IRAM_to_DDRv2 test

t5: IRAM_to_DDRv1 test

t6: read noise walking ones and zeros test

- « Previous

- Next »