- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- Home

- :

- モデルベース・デザイン・ツールボックス(MBDT)

- :

- NXPモデルベース・デザイン・ツールナレッジベース

- :

- PMSM Motor Control Application for S32K396 with MBDT and Custom Code

PMSM Motor Control Application for S32K396 with MBDT and Custom Code

- RSS フィードを購読する

- 新着としてマーク

- 既読としてマーク

- ブックマーク

- 購読

- 印刷用ページ

- 不適切なコンテンツを報告

PMSM Motor Control Application for S32K396 with MBDT and Custom Code

PMSM Motor Control Application for S32K396 with MBDT and Custom Code

PMSM Motor Control Application for S32K396 with MBDT and Custom Code

Examples were designed on XS32K396-BGA-DC EVB and 3-phase PMSM pre-driver board(with connection cable)

MATLAB Simulink-based project (s32k396_pmsm_mc_mbdt) is build using Model-Based Design Toolbox (MBDT) and can be downloaded from NXP Model-Based Design Toolbox for S32K3xx - version 1.5.0 or newer releases.

For all models file and document, please find the attachment.

1. Introduction

This article aims to introduce and demonstrate how a PMSM control algorithm targeting the S32K396 MCU can be designed inside the Simulink ® environment. The demo introduced by this article is built using (but is not part of) the NXP ® Model-Based Design Toolbox (MBDT) for S32K3xx, hence it has not been fully tested inside the MBDT development environment, neither been passed through the verification and validation processes imposed for the applications delivered within the toolbox. The demo presented in the following article is just an example of how NXP's software and hardware products can be used for developing motor control algorithms, using the MATLAB ® and Simulink ecosystem capabilities.

The S32K39 is an Arm ® Cortex ® -M7 based Microcontroller series which runs up to 320 MHz, which contains an advanced motor control co-processor (eTPU) designed with the purpose of offloading the main CPU from motor control tasks, and a high-resolution PWM. It is developed to meet the next generation SiC traction inverter requirements and to enable high efficiency and low latency features. Also, S32K39 is suitable for applications like Automotive Inverter, On-board Charger (OBC), and High-performance Battery Management System (BMS).

The NXP Model-Based Design Toolbox (MBDT) is a comprehensive collection of tools that plug into the MATLAB and Simulink model-based design environment to support verification, validation, and rapid prototyping of complex algorithms for real targets based on NXP microcontrollers and processors.

For enabling hardware access from the Simulink applications development environment, MBDT offers integration with Real-Time Drivers (RTD) for controlling the system and peripheral devices. The configuration of the on-board peripherals, pins, and clocks, is realized by enabling the integration with dedicated configuration tools, like NXP’s S32 Configuration Tools delivered inside the toolbox, and EB Tresos. MBDT delivers a library of Simulink blocks, which implement functionalities of MCU peripherals and generate code on top of specific drivers' functions. Together with these, the toolbox integrates the AMMCLIB library, for facilitating the development of motor control algorithms. The toolbox offers support for software-in-the-loop and processor-in-the-loop (SIL and PIL) development workflows, allowing the design, verification and validation at each development step. It also generates and deploys code automatically, from Simulink models, to start up the MCU and run complex applications, which enables control engineers and embedded developers to shorten project life cycles.

Hence, by using NXP's Model-Based Design Toolbox, complex algorithms, which can be modelled, simulated and verified hardware independently, using the rich ecosystem of solutions the MathWorks ® environment provides, can be tailored to become hardware aware for targeting specific NXP platforms.

The S32K39 is an Arm Cortex-M7-based Microcontroller series, which contains an advanced motor control co-processor (eTPU), a high-resolution PWM, and runs up to 320 MHz. It is developed to meet the next-generation SiC traction inverter requirements and to enable high efficiency and low latency features. Also, S32K39 is suitable for applications like Automotive Inverter, On-board Charger (OBC), and High-performance Battery Management System (BMS).

This demo aims to give a quick start guide on building up a motor control system with NXP MBDT on S32K396. It contains the environment setup, module configuration, system initialization, and interruption structure, Permanent Magnet Synchronous Motor (PMSM) control algorithm, and FreeMASTER configuration.

2. Hardware and Software Setup

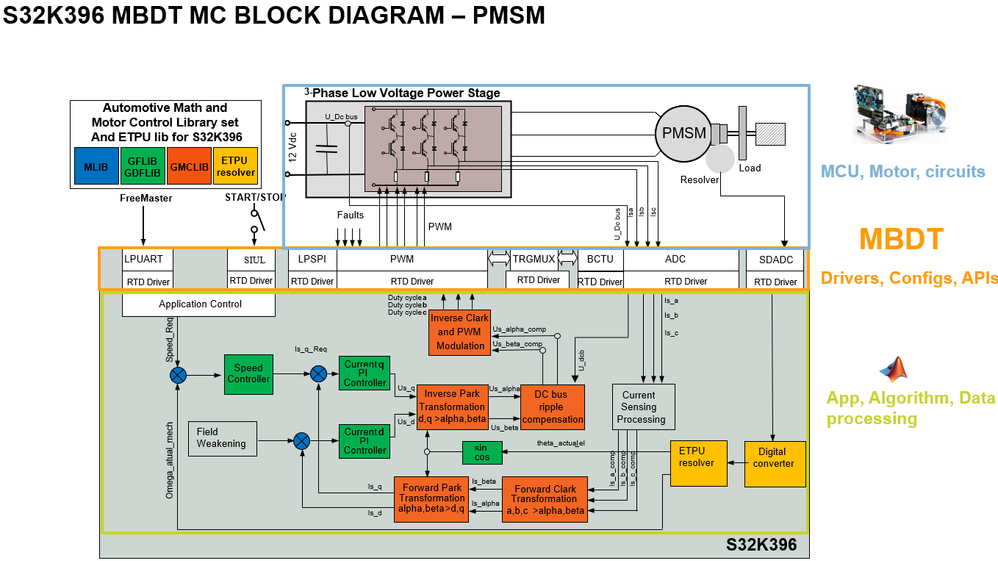

For more details on how this can be achieved, the following diagram is introduced, mapping the PMSM algorithm on top of the existing hardware for the S32K396 MCU. The App, Algorithm, Data processing section can be implemented using Simulink libraries blocks, AMMCLib blocks and Simulink custom code functionalities to include eTPU drivers that address this co-processor access and control. The MBDT section is covered by the blocks provided by the toolbox, ensuring hardware access to the peripherals implied in such applications, while the MCU, Motor, circuits refers to the hardware elements used for the design.

The following picture presents the application mapping of the software and hardware used to develop PMSM Motor Control on S32K396:

Figure 2.1 Application mapping of software and hardware used to develop PMSM Motor Control on S32K396

For an overview of the elements necessary for modeling such a diagram inside a Simulink model, the following picture is introduced, showcasing the software components and functionalities that can be used inside this scenario, which will be furtherly detailed in the following sections.

Figure 2.2 Software Components for modeling the PMSM Motor Control on S32K396

This demo aims to give a quick start guide on building up a motor control system with NXP MBDT on S32K396. It contains the environment setup, module configuration, system initialization, and interrupts structure, Permanent Magnet Synchronous Motor (PMSM) control algorithm, and FreeMASTER configuration, demonstrating the following features:

- 3-phase PMSM speed Field Oriented Control.

- Integrated eTPU software resolver functions for position and speed measurement.

- Develop PIL models for hardware simulation and PIL test.

- Application control user interface using FreeMASTER debugging tool. (Please get more details on FreeMASTER from section 9 and the references part)

2.1 Required software

- S32 Design Studio for S32 Platform 3.5

- EB tresos Studio 29.0

- FreeMASTER 3.2

- MATLAB R2023b with “Embedded Coder ® for ARM Cortex-M Processors”

- NXP Model-Based Design Toolbox for S32K3xx version 1.5.0

- SW32K3_S32M27x_RTD_R21-11_4.0.0_P19(contained in the toolbox)

2.2 Required hardware

The following is a list of required hardware:

- Boards: XS32K396-BGA-DC EVB and MC33937 MOSFETs pre-driver (with connection cable).

- Motor: 3-phase PMSM TGT2-0032-30-24.

- Debugger: Lauterbach for Cortex-M7 or Multilink PE micro debugger.

- Power: 12V power supply for EVB and 24V power supply for pre-driver board.

- PCIE Cable.

- Micro USB Cable.

Note: The debugger Lauterbach is not integrated in the MBTD tool, it is only a method to debug the code.

2.3 Prepare the demo

The central controller EVB board runs the control algorithm, and the pre-driver drives the motor. Connect the hardware devices with the following steps:

Figure 2.3.1 Hardware Setup

- Connect the PMSM’s three-phase winding to J4 on the pre-driver and connect the resolver signal to J8 on the pre-driver.

- Connect motor control signals from J14 on the pre-driver to J44 on the EVB board.

- Connect the debugger between JTAG J20 and the computer.

- Connect the USB cable between J15 and the computer, then the EVB LED D30 will be solid green.

- Plug in the 12V power supply port J1 on the EVB board, then the EVB LED D4 will be solid green.

- Plug in the 24V driver power on port J13 of the pre-driver, and then the pre-driver LED D14 will be solid yellow.

2.4 Running the demo

Please refer to the S32K396_MBDT_BASED_MOTOR_CONTROL_Quick_Start_Guide_0_9_0.pdf in the project doc folder.

3. Demo blocks introduction

In the following figure, an overview of the main Simulink model is presented. The motor control application model has the following structure: Initialization and Interrupt.

Figure 3.1 Simulink Application Top Model

- Var Init contains the variables used by the model and can be visualized in FreeMASTER.

- Initialize subsystem contains the FreeMASTER configuration, state machine and control mode initialization, and BCTU hardware trigger enablement. This subsystem is executed only once, at the beginning of the application.

- Hardware Interrupt Callback calls the motor control block to run. This block delivered by the MBDT, allows the implementation of specific actions inside a callback function which is executed when an interrupt occurs on the configured peripheral instance, at a specific event. Callbacks are associated with specific events inside the configuration project used with the model, which ensures the on-board configuration of the peripherals, pins, and clocks.

- Motor Control function-call subsystem runs every time an ADC interrupt occurs.

Inside the Motor Control subsystem, as illustrated below, the ADC hardware trigger is disabled (Step 1) until the PMSM control algorithm calculation is finished (Step 2), and reenabled at the end of this computation (Step 3). The priority order of the generated code is achieved by setting the “Priority” value, accessible inside the Properties of each Simulink block.

Figure 3.2 Motor Control Subsystem

The pmsm_mc_algo algorithm is a subsystem reference model. It collects the input sensor signals, calculates the PMSM control algorithm, and drives PWMs to generate the output voltage. Following figure shows the main blocks:

- Current Voltage Measurement reads BCTU FIFO data and calls the following blocks.

- Board Buttons control the motor with hardware pins on board.

- State Machine subsystem contains the Stateflow® of the motor control application and each state will call a dedicated function block.

- Enable Outputs enables the PWM output function.

- Disable Outputs disables the PWM output function.

- Green LED Toggle controls a green LED to blink.

- Update PWM calls the MBDT PWM block to update the duty cycle value.

Figure 3.3 PMSM Motor Control Algorithm

4. Startup initialization

The startup initialization is a subsystem of the initialize function block. It’s used to configure some basic functionality at the start of the application:

- FreeMASTER Config which configures the UART to communicate with FreeMASTER GUI. FreeMASTER Config block allows the users to configure the FreeMASTER embedded-side software driver, which implements the serial interface between the application and the host PC. It actually inserts the service in the application, and it is the only one mandatory to be added to the Simulink canvas in order to have the FreeMASTER functionality available.

- Gpt_StartTimer enables one GPT channel for pre-driver MC33937 dead time configuration.

- Adc_CtuEnableHwTrigger enables the BCTU hardware trigger feature.

- Set the event and state to reset values and set the default control mode as speed control.

Figure 4.1 Initialize Subsystem

5. Interrupt and measurements

This part describes the configuration and usage of BCTU and ADC modules for analog data capturing. BCTU is triggering parallel ADC conversions for 3-phase current measurements. After all measurements are fulfilled, the BCTU FIFO notification is used to read the stored ADC data and to call the main control loop of the application for further processing.

5.1 Interrupt configuration and service

The following picture shows the configuration for the BCTU FIFO notification callback feature. The BCTU FIFO 1 is used to store the ADC results, the watermark value decides when to call the function configured in the notification. Also, enabling the BCTU IRQ in configuration is required.

Figure 5.1.1 BCTU Watermark Notification Configuration

Figure 5.1.2 BCTU Interrupt Enablement

In the Simulink model, the configured notification for BCTU is selected inside the Hardware Interrupt Callback block. This will execute the connected function-call subsystem when the End-of-Conversion interrupt occurs.

Figure 5.1.3 Interrupt Callback Subsystem

5.2 Measurements of currents and voltage

This section describes the measurement of analog quantities: 3-phase currents and DC bus voltage. BCTU receives the hardware trigger to start the ADC measurements (parallel conversions). Once all results have been stored into the FIFO, the interrupt will call the main control loop. BCTU FIFO notification is used to call the main loop of the motor control, which ensures the sampling is finished before using them. How to get sampled values for processing is presented in this section. The following picture shows the steps and operations to transfer the current and voltage to their real physical values. To acquire the currents and voltage from BCTU FIFO for further processing, the Adc block from MBDT library is used and the Adc_CtuReadFifoData is selected.

Figure 5.2.1 Process converted data to physical values

6. eTPU resolver

Software resolver is now widely used in the Inverter application, which can help to save the BOM (Bill of Materials) cost. The eTPU on S32K39 supplies a function to the customer to implement a software resolver via a software package. It uses one eTPU channel to generate a 50% duty-cycle PWM output signal to be passed through an external low-pass filter and used as a resolver excitation signal. In the resolver position sensor, this excitation signal is modulated by the sine and cosine of the actual motor angle. The feedback Sine and Cosine signals are sampled by an SDADC and processed by a followed DSP. The conversion results can be transferred to eTPU DATA RAM by DMA. Then, the eTPU can process the digital samples of resolver output signals and output the position and speed for the FOC. For more details about the eTPU resolver, please refer to AN13038.

Figure 6.1 eTPU Resolver Diagram

6.1 Resolver functions call in MATLAB

The eTPU Resolver Block is not yet available in MBDT. The System Output block is used to insert custom code for getting resolver data.

The getMotorControlResolver(&mbd_ebt_DW_FOC_one.Resolver_SW) function is used to get resolver data.

Figure 6.1.1 Simulink custom code for eTPU access

The speed and angle are estimated from the Resolver Angle subsystem and are provided to the slow & fast control loops. Finally, the sine and cosine values from the estimated electrical angle are computed.

Figure 6.1.2 Computation of the speed and angle

7. State machine

This is a critical part of the motor control application model, each state has a dedicated block to handle the related functions.

Figure 7.1 Motor Control States Implementation

The state machine block controls the workflow of the motor control application, it has been designed using Stateflow.

Figure 7.2 Finite State Machine

8. PWM control and update

Subsystems Enable Outputs and Disable Outputs control the output of PWM. They are called by the state functions. In the subsystems, the flag PWM_enabled and gate driver output status are changed via the pwm_enable_output or the pwm_disable_output function.

Figure 8.1 Enable Outputs Subsystem

Figure 8.2 Disable Outputs Subsystem

Update PWM subsystem is used to generate the PWM duty cycle value according to the output from the control loop. This value is eventually set for the FlexPWM peripheral to generate PWM voltages to drive the motor. The FlexPWM is configured to generate complementary signals for bridges and is updated synchronously according to a reload signal in the EB project. Here it is only needed to pass the duty cycle values to the Pwm function in the model.

Figure 8.3 PWM Duty Cycle Values Computation

Figure 8.4 PWM Duty Cycle Values Update

9. Buttons

Buttons are used to control the running of the motor. The algorithm reads the value of the button from the board to change the running state or speed. The Dio block in the MBDT library is used to read the value of I/O. The I/O port of buttons has been configured in the EB project. Two buttons on the board are used to increase or decrease the running speed of the motor. Also, they are used to clear the fault information when pressed together. One button is used to control the start or stop of the motor. The following picture shows the subsystem for the button control logic.

Figure 9.1 Buttons Control Logic

10. FreeMASTER GUI

FreeMASTER is a user-friendly real-time debug monitor and data visualization tool that enables runtime configuration and tuning of embedded software applications. To enable FreeMASTER in this project, the interface needs to be configured first.

MBDT supplies blocks to support FreeMASTER’s configuration. In this project, LPUART_0 is used to transmit data between the GUI and the board. The following figure shows the MCAT GUI, which can be used to observer parameters/variables and also used to control the status of the motor. It can be found in the project folder, under “./mbd/FreeMASTER_control”.

Figure 10.1 MCAT GUI

11. PIL model

PIL represents a verification and validation step where the code generated for the developed control algorithm is cross-compiled and deployed on the target hardware, then stimulated with test inputs from the Simulink application executed on the host PC, containing the plant model. The test inputs are sent to the target via Serial Communication. By enabling this simulation mode, users could test the performance of the processor long before having the final hardware design, testing whether the model and the generated code are numerically equivalent, and being able to perform code execution profiling.

Hence, for this motor control design, we have also developed a PIL model (pil_model_ebt) used to verify the model-generated code on the S32K396 microcontroller. The PIL top model contains two parts: Simulation Model and Hardware Model. The Simulation Model contains the model of the real system (pre-driver and PMSM), as depicted inside Section 11.1. The Hardware Model contains the control algorithm which is the same as in the application previously introduced (mbd_ebt.slx). For the hardware Model part, the code will be generated, built and an executable file will be deployed on hardware. Input and output signals processing blocks will generate the necessary test inputs for the code that runs on the hardware controller, as depicted in the screenshot below.

Figure 11.1 PIL Top Model

11.1 PIL Model introduction

The PIL top model runs the simulation model part inside the Simulink environment and exchanges signal data with the hardware controller through Serial Communication.

11.2 Simulation model

The simulation model simulates the hardware of the pre-driver and PMSM using Simscape™ Electrical™ blocks.

- Duty to PWM simulates the function of a central aligned FlexPWM with the frequency of 20kHz.

- Inverter simulates three-phase full-bridge circuit with the same parameters as in MC33937 MOSFETs pre-driver.

- PMSM is defined with the same parameters as the real motor.

- Resolver is simplified as an ideal rotational motion sensor.

- Phase Current Sensing, Bus Current Sensing and Bus Voltage Sensing are built up regarding MC33937 MOSFETs pre-driver.

- SARADC block samples signal simultaneously with the PWM module and generates a function call after data conversion is completed.

Figure 11.2.1 PIL Host Model

11.3 Hardware model

The hardware model is a referenced model that generates code and deploys it into the microcontroller. It’s called by ADC conversion completion signal.

In the initialization process, it initializes the global variables and drivers. In the normal running process, when a function call comes, the model will calculate the input signal, run the state machine, and generate the output signal in the order defined in subsystem “pmsm_mc_algo”.

Figure 11.3.1 PIL Target Model

12. Conclusions

NXP's MBDT enables the usage of hardware optimized tools: Real-Time Drivers (RTD), Automotive Math and Motor Control Library (AMMCLib), Configuration (S32 Configuration Tools and EB Tresos), and Build Tools in the Simulink environment.

This article gives examples on the construction and environment setup process for designing motor control models, and how they can be verified and validated through PIL simulation before being deployed on the target hardware. It focuses on how NXP’s Model-Based Design Toolbox and the software NXP provides could be used together with MathWorks tools and functionalities for rapid prototyping complex embedded designs on NXP targets. Together with the rich MathWorks ecosystem, it allows users to model complex algorithms, and generate optimized code for the NXP’s microcontrollers and processors, ensuring thus a fast and reliable programming environment.

Please note that the demo was not fully tested inside MBDT ecosystem and application development workflow it proposes, as the depicted example uses custom code functionalities for addressing the eTPU co-processor access, currently not supported by MBDT, and a specific version of the RTD, different than the one the toolbox was released and tested with. For more information about MBDT, tutorials, webinars and other resources, please visit the MBDT Community Page.

You might also visit NXP.com for additional information on the development ecosystem that NXP offers.

13. References

- 3-phase Motor Control Kit with S32K396

- The workshop “3-Phase PMSM Control Workshop with NXP's Model-Based Design Toolbox” from NXP Community

- Module 4: Space Vector Modulation from NXP Community

- MC33937: 3-Phase Field Effect Transistor Pre-driver.

- Automotive Math and Motor Control Library Set for NXP S32K3xx devices.

- FreeMASTER Run-Time Debugging Tool.

- Application Note: AN13902: 3-Phase Sensorless PMSM Motor Control Kit with S32K344 using MBDT Blocks