- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- Home

- :

- General Purpose Microcontrollers

- :

- Kinetis Microcontrollers

- :

- MKW30Z temperature sensor calibration

MKW30Z temperature sensor calibration

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

KW40Z_Connectivity_Software_1.0.1 (KSDK_1.3.0) IAR 7.5

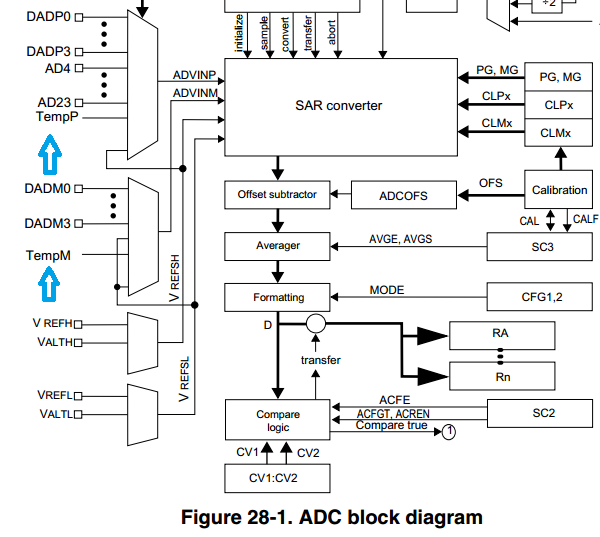

MKW40Z/30Z/20Z Reference Manual, Rev. 1.2, 10/2015

28.4.8 Temperature sensor links to

Temperature Sensor for the HCS08 Microcontroller Family (document AN3031).

http://cache.freescale.com/files/microcontrollers/doc/app_note/AN3031.pdf

witch presents a calibration implementation:

Floating-Point

Calibrated (3 Points) Typical Accuracy ± 2.5degs C

Uncalibrated Typical Accuracy ± 8degs C

Fixed-Point

Calibrated (3 Points) Typical Accuracy ± 12degs C

Uncalibrated Typical Accuracy ± 18degs C

In conclusion having fixed-point arithmetic calibrated and un-calibrated does not help you at all...

Having no calibration at all and floating point algo goes to ±8 deg C with is quite hight.

3 point calibration gives good result but is hard to achieve in production (as time and resources).

In production, one point calibration is the easiest to do - measure by chip and measure by reference thermometer near chip.

(@ room temperature)

The HCS08 AN3031 document is accurate on MKW30Z ?

Is some sort of calibration implemented in framework ?

What would be the Calibrated 1 Point Typical Accuracy ?

Thank you,

Lucian

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

That should work fine -- so your calibration process will yield a 'better' V_TEMP25 (instead of the #define), OR maybe you will want to define a different calibration point (if you can in production) closer to the 'temp range of interest', like around 60C for STANDARD_TEMP; but I WOULD use a constant for adcr100m(ADCR_VDD*100/3300), since your Vdd 'reference' will already be BETTER than the on-chip bandgap. And with that, slope error, and others you can expect 'worst case' +/-15C tolerance, usually MUCH better. You will want to 'estimate' the on-chip to LED-chip differential in 'steady state' in the assembled product.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

On-chip temperature Calculations in which I show that with a 'good reference' and single-point (offset) calibration you could guarantee +/-2C 0to50C, using 32bit integer math.

Applies, as far as I know, to ANY former-Freescale microcontroller's temp-sense module (with allowance for the fact that 'older' parts published two slope factors).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I understand that the AN is quite old and should be updated !

(Motorola, Freescale, NXP, Qualcomm)

The MKW30Z chip can use floating point math.

The chip measures die temperature or ambient temperature ?

6.4.1 Thermal operating requirements

TJ Die junction temperature –40 100 °C

TA Ambient temperature –40 85 °C

(Max/min expected temp value ?)

How many bits can we use (meters) ?

differential 16-bit, 13-bit, 11-bit, and 9-bit modes

single-ended 16-bit, 12-bit, 10-bit, and 8-bit modes

ADC reference voltage selection.

Variants:

- internal band-gap

- external LDO NCP1117 (3.235V -> 3.365V) (Tlow = 0°C ,Thigh = 125°C)

- external special reference

- external DCDC convertor (buck/boost)

Witch is better NCP1117 3.3V (reference design) or internal band-gap ?

Possible calibrations:

No Calibrattion

1 point calibration (Vtemp25C)

2 point calibration (Vtemp25C + hot slope)

2 point calibration (Vtemp25C + cold slope)

3 point calibration (Vtemp25C + hot, cold slope)

n point calibration

Should we use a dual slope factor ( -40 to 25 to 100) or single ?

What about MKW30Z framework implementations ?

On frdm_kw40z_demo_1.0 - current chip temperature with a 0.01 °C resolution.

Seems a no calibration implementation.

#define TEMPERATURE_SENSOR_V_BANDGAP_mV 1000 /*!< Bandgap ADC channel voltage (in mV) */

#define TEMPERATURE_SENSOR_ADC_RESOLUTION 32768 /*!< Expanded resolution value 2^Resolution */

#define TEMPERATURE_SENSOR_VTEMP25_mV 716 /*!< Temperature sensor voltage @25C defined by the datasheet */

#define TEMPERATURE_SENSOR_SLOPE_uV 1620 /*!< Temperature sensor slope (in uV) defined by the datasheet */

int16_t temperature_sensor_get_chip_temperature (void){

adc16_status_t result;

int16_t bandgapVoltageAdcReading, temperatureChannelAdcReading;

int16_t vReference, vTemperatureSensor;

int16_t temperatureReading;

/* Start Bandgap Voltage Measurements */

result = ADC16_DRV_ConfigConvChn(TEMPERATURE_SENSOR_ADC_INSTANCE, 0, &temperatureSensorBandgapVoltageChannel);

if(result != kStatus_ADC16_Success)

return kTemperatureSensorConversionStartError;

/* Wait for bandgap voltage measurement reading */

ADC16_DRV_WaitConvDone (TEMPERATURE_SENSOR_ADC_INSTANCE, 0);

/* Get bandgap measurement */

bandgapVoltageAdcReading = ADC16_DRV_GetConvValueSigned (TEMPERATURE_SENSOR_ADC_INSTANCE, 0);

/* Start Temperature Channel Measurements */

result = ADC16_DRV_ConfigConvChn(TEMPERATURE_SENSOR_ADC_INSTANCE, 0, &temperatureSensorChipTemperatureChannel);

if(result != kStatus_ADC16_Success)

return kTemperatureSensorConversionStartError;

/* Wait for temperature channel measurement reading */

ADC16_DRV_WaitConvDone (TEMPERATURE_SENSOR_ADC_INSTANCE, 0);

/* Get temperature channel measurement */

temperatureChannelAdcReading = ADC16_DRV_GetConvValueSigned (TEMPERATURE_SENSOR_ADC_INSTANCE, 0);

/* Calculate Reference Voltage */

vReference = (int16_t)((TEMPERATURE_SENSOR_V_BANDGAP_mV * TEMPERATURE_SENSOR_ADC_RESOLUTION)/bandgapVoltageAdcReading);

/* Calculate Temperature Sensor Voltage */

vTemperatureSensor = (int16_t)((vReference*temperatureChannelAdcReading)/TEMPERATURE_SENSOR_ADC_RESOLUTION);

/* Obtain temperature measurement*/

temperatureReading = 2500 - (((vTemperatureSensor - TEMPERATURE_SENSOR_VTEMP25_mV)*1000*100)/TEMPERATURE_SENSOR_SLOPE_uV);

return temperatureReading;

}

Another implementation bluetooth_temperature_sensor on temp_sensor.c

/*!

* @brief These values are used to get the temperature. DO NOT MODIFY

* The method used in this demo to calculate temperature of chip is mapped to

* Temperature Sensor for the HCS08 Microcontroller Family document (Document Number: AN3031)

*/

#define ADCR_VDD (65535U) // Maximum value when use 16b resolution

#define V_BG (1000U) // BANDGAP voltage in mV (trim to 1.0V)

#define V_TEMP25 (716U) // Typical converted value at 25 oC in mV

#define M (1620U) // Typical slope:uV/oC

#define STANDARD_TEMP (25)

#define ADC16_INSTANCE (0) // ADC instacne

#define ADC16_TEMPERATURE_CHN (kAdc16Chn26) // Temperature Sensor Channel

#define ADC16_BANDGAP_CHN (kAdc16Chn27) // ADC channel of BANDGAP

#define ADC16_CHN_GROUP (0) // ADC group configuration selection

uint32_t adcValue = 0; // ADC value

uint32_t adcrTemp25 = 0; // Calibrated ADCR_TEMP25

uint32_t adcr100m = 0; // calibrated conversion value of 100mV

adc16_converter_config_t adcUserConfig1; // structure for user config

int32_t TempSensor_GetTemperature(void)

{

int32_t currentTemp = 0;

adc16_chn_config_t chnConfig;

// Configure the conversion channel

// differential and interrupt mode disable.

chnConfig.chnIdx = (adc16_chn_t)ADC16_TEMPERATURE_CHN;

#if FSL_FEATURE_ADC16_HAS_DIFF_MODE

chnConfig.diffConvEnable = false;

#endif

chnConfig.convCompletedIntEnable = false;

// Software trigger the conversion.

ADC16_DRV_ConfigConvChn(ADC16_INSTANCE, ADC16_CHN_GROUP, &chnConfig);

// Wait for the conversion to be done.

ADC16_DRV_WaitConvDone(ADC16_INSTANCE, ADC16_CHN_GROUP);

// Fetch the conversion value.

adcValue = ADC16_DRV_GetConvValueSigned(ADC16_INSTANCE, ADC16_CHN_GROUP);

// Calculates adcValue in 16bit resolution

// from 12bit resolution in order to convert to temperature.

#if (FSL_FEATURE_ADC16_MAX_RESOLUTION < 16)

adcValue = adcValue << 4;

#endif

// Multiplied by 1000 because M in uM/oC

// Temperature = 25 - (ADCR_T - ADCR_TEMP25) * 100*1000 / ADCR_100M*M

currentTemp = (int32_t)(STANDARD_TEMP - ((int32_t)adcValue - (int32_t)adcrTemp25) * 100000 /(int32_t)(adcr100m*M));

// Pause the conversion.

ADC16_DRV_PauseConv(ADC16_INSTANCE, ADC16_CHN_GROUP);

return currentTemp;

}

/*!

* @brief Parameters calibration: VDD and ADCR_TEMP25

*

* This function used BANDGAP as reference voltage to measure vdd and

* calibrate V_TEMP25 with that vdd value.

*/

static void calibrateParams(void)

{

adc16_chn_config_t adcChnConfig;

#if FSL_FEATURE_ADC16_HAS_HW_AVERAGE

adc16_hw_average_config_t userHwAverageConfig;

#endif

pmc_bandgap_buffer_config_t pmcBandgapConfig = {

.enable = true,

#if FSL_FEATURE_PMC_HAS_BGEN

.enableInLowPower = false,

#endif

#if FSL_FEATURE_PMC_HAS_BGBDS

.drive = kPmcBandgapBufferDriveLow,

#endif

};

uint32_t bandgapValue = 0; // ADC value of BANDGAP

uint32_t vdd = 0; // VDD in mV

#if FSL_FEATURE_ADC16_HAS_CALIBRATION

// Auto calibration

adc16_calibration_param_t adcCalibraitionParam;

ADC16_DRV_GetAutoCalibrationParam(ADC16_INSTANCE, &adcCalibraitionParam);

ADC16_DRV_SetCalibrationParam(ADC16_INSTANCE, &adcCalibraitionParam);

#endif // FSL_FEATURE_ADC16_HAS_CALIBRATION.

// Enable BANDGAP reference voltage

PMC_HAL_BandgapBufferConfig(PMC_BASE_PTR, &pmcBandgapConfig);

#if FSL_FEATURE_ADC16_HAS_HW_AVERAGE

// Use hardware average to increase stability of the measurement.

userHwAverageConfig.hwAverageEnable = true;

userHwAverageConfig.hwAverageCountMode = kAdc16HwAverageCountOf32;

ADC16_DRV_ConfigHwAverage(ADC16_INSTANCE, &userHwAverageConfig);

#endif // FSL_FEATURE_ADC16_HAS_HW_AVERAGE

// Configure the conversion channel

// differential and interrupt mode disable.

adcChnConfig.chnIdx = (adc16_chn_t)ADC16_BANDGAP_CHN;

#if FSL_FEATURE_ADC16_HAS_DIFF_MODE

adcChnConfig.diffConvEnable = false;

#endif

adcChnConfig.convCompletedIntEnable = false;

ADC16_DRV_ConfigConvChn(ADC16_INSTANCE, ADC16_CHN_GROUP, &adcChnConfig);

// Wait for the conversion to be done

ADC16_DRV_WaitConvDone(ADC16_INSTANCE, ADC16_CHN_GROUP);

// Get current ADC BANDGAP value and format it.

bandgapValue = ADC16_DRV_GetConvValueSigned(ADC16_INSTANCE, ADC16_CHN_GROUP);

// Calculates bandgapValue in 16bit resolution

// from 12bit resolution to calibrate.

#if (FSL_FEATURE_ADC16_MAX_RESOLUTION < 16)

bandgapValue = bandgapValue << 4;

#endif

// ADC stop conversion

ADC16_DRV_PauseConv(ADC16_INSTANCE, ADC16_CHN_GROUP);

// Get VDD value measured in mV

// VDD = (ADCR_VDD x V_BG) / ADCR_BG

vdd = ADCR_VDD * V_BG / bandgapValue;

// Calibrate ADCR_TEMP25

// ADCR_TEMP25 = ADCR_VDD x V_TEMP25 / VDD

adcrTemp25 = ADCR_VDD * V_TEMP25 / vdd;

// Calculate conversion value of 100mV.

// ADCR_100M = ADCR_VDD x 100 / VDD

adcr100m = ADCR_VDD*100/ vdd;

// Disable BANDGAP reference voltage

pmcBandgapConfig.enable = false;

PMC_HAL_BandgapBufferConfig(PMC_BASE_PTR, &pmcBandgapConfig);

}

What about these implementations ?

How good are they ?

Thank you,

Lucian.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I can't go thru all that code in detail, but the concepts look like they follow my integer-implementation outlines -- with some debugging you can confirm the details. temperature_sensor_get_chip_temperature looks most like my sequence, where you could 'skip' the vReference calculation (and use a constant) by using either 'good LDO' Vdd or a GOOD external voltage reference. They also use some int16 where you might as well use int32 on a 32-bit processor.

The temperature measured is, of course, the CPU-chip's die temperature, more specifically 'at some particular point' on the die, but I suppose we can assume a 'small differential' across the die.

I would convert 16-bits; the Temp and BG channels are single-ended.

The internal bandgap is +/-2% 0to50C, +/-3% otherwise. Your NCP LDO is +/-2% over that specified temp range, so 'somewhat better', but will contribute a +/-10C error-band, as per my writeup. The temperature-cell-measurements are 'absolute voltages', and thus the conversion accuracy is directly related to the reference accuracy, and because the temperature-result is a DIFFERENCE of two similar numbers, conversion inaccuracy nets a much larger result-error. To expect some 'real accuracy' will REQUIRE something like the 0.1%-accurate reference I suggest --- HOPEFULLY you have some other analog-functions for your system that would benefit from this precision reference!

AT LEAST make a single-point calibration (to remove the +/-6.2C offset error), where you take the 'measured temperature cell' voltage at a stable operating point, and as compared to a co-located reference-temperature in your production-test-fixture, will allow you to 'assume' the 1.62mV/C slope (617mC/mV) is 'close', and run down that slope to what the measured temperature cell value would be at 25C, and save THAT as Vtemp25mv. The published slope error is only upto +/-.043C/C, so even at a 50C difference from 25C it only opens a +/-2.5C error-band, and is probably NOT worth the extra production time to correct from a 2nd calibration point. We do assume here that the temp-cell output is LINEAR, which of course is only an approximation. I assume the 'older chips' supplied two slopes to try to 'help' that linearization -- I don't personally know what any non-linearity error will contribute.

If you HAVE no 'other good use' for accurate Vref, I simply suggest dropping an ADT75A onto your I2C bus...precalibrated to deliver +/-3C -55to125C@Vdd=3.3V, and it WON'T be influenced (directly, at least!) by CPU-chip-heating.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

In my application I have the chip surrounded by a lot of LEDs in a close box, lamp head.

At some critical threshold temperature I will start dimm all outputs as some factor proportional to temperature.

If the temperature continue to rise another failure threshold will be set and all outputs will be off.

With some hysteresis after cooling the leds will work again.

Considering die junction temperature –40 100 °C surrounding chip ambient temperature is –40 85 °C

Worst used leds have Operating Temperature Range Topr -40°C to +80°C

So the region of interest is 60C - 75C ambient near chip temperature.

The board was design with a lot of ground plane to absorb and disperse the led temperature on surface

and a ~uniform temperature distribution on PCB.

I don't have any other other analog functions that require a 'good' reference.

If I use the LDO as reference will be an offset error of +/-10C error-band ?

If an 1 point calibration will be done, the reference thermometer will be close to chip.

The error is due to 2 conversions TempP and TempM.

The function TempSensor_GetTemperature use the values

uint32_t adcrTemp25 = 0; // Calibrated ADCR_TEMP25

uint32_t adcr100m = 0; // calibrated conversion value of 100mV

adc16_converter_config_t adcUserConfig1; // structure for user config

// Multiplied by 1000 because M in uM/oC

// Temperature = 25 - (ADCR_T - ADCR_TEMP25) * 100*1000 / ADCR_100M*M

currentTemp = (int32_t)(STANDARD_TEMP - ((int32_t)adcValue - (int32_t)adcrTemp25) * 100000 /(int32_t)(adcr100m*M));

generated by function calibrateParams

// Get VDD value measured in mV

// VDD = (ADCR_VDD x V_BG) / ADCR_BG

vdd = ADCR_VDD * V_BG / bandgapValue;

// Calibrate ADCR_TEMP25

// ADCR_TEMP25 = ADCR_VDD x V_TEMP25 / VDD

adcrTemp25 = ADCR_VDD * V_TEMP25 / vdd;

// Calculate conversion value of 100mV.

// ADCR_100M = ADCR_VDD x 100 / VDD

adcr100m = ADCR_VDD*100/ vdd;

and the constants:

#define ADCR_VDD (65535U) // Maximum value when use 16b resolution

#define V_BG (1000U) // BANDGAP voltage in mV (trim to 1.0V)

#define V_TEMP25 (716U) // Typical converted value at 25 oC in mV

#define M (1620U) // Typical slope:uV/oC

#define STANDARD_TEMP (25)

Thank you,

Lucian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

That should work fine -- so your calibration process will yield a 'better' V_TEMP25 (instead of the #define), OR maybe you will want to define a different calibration point (if you can in production) closer to the 'temp range of interest', like around 60C for STANDARD_TEMP; but I WOULD use a constant for adcr100m(ADCR_VDD*100/3300), since your Vdd 'reference' will already be BETTER than the on-chip bandgap. And with that, slope error, and others you can expect 'worst case' +/-15C tolerance, usually MUCH better. You will want to 'estimate' the on-chip to LED-chip differential in 'steady state' in the assembled product.