- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

What causes a PCF8883 lock up state (output continuously high)?

We are using the PCF8883 capacitive sensor and have been experiencing a lock up state I couldn't find mentioned in the datasheet/app note. If the sensitivity of CPC is set closer to the upper limits or the sampling frequency is increased, the sensor can be put in a state where a sense event triggers and the output remains high forever after. The type pin is grounded (pushbutton mode), but the capacitive event should clear when your hand is pulled away. This lock up does not occur with middle range CPC and CLIN values. We are trying to push the sensing distance out as far as possible, so there may be an increased susceptibility to noise, but it only seems to lock after a sense trigger. I am just wondering if anyone knows what might be the root cause.

Hi Dave,

We are aware of these documents and followed the recommended values.. Please try the eval kit and set it in push button mode and press for 5 second.. It will stuck high.. I really need answer to this as we may have to change our design if the chip is not suitable for push button mode.

Thanks for your help.

Hello all,

Please refer to the following information in order to avoid the behavior mentioned:

-One issue with the touch switches is the power supply. The touch switches work well from battery power or unswitched regulators but don’t work well from switched regulators. The limitation is related to noise immunity. Since the device is a state machine with no data processing, noise from switching AC/DC power supplies causes low sensitivity. The detection algorithm needs a counter to go with 1kHz and detect 64 consecutive samples and when noise comes in the counter is reset and the capacitive event will not be detected.

The other is the mode of operation. Two of them do not work well which are push button and toggle. The only good consistent operation is pulse since there is a defined operation for each capacitive event and the device don’t need to remember the last event.

-In regard with the Ccpc value, the most important side effect of increasing Ccpc is that also the noise sensitivity increases. Another side effect is the size of the part. Just to remember, the Ccpc part should be a X7R or comparable part. If the low sensitivity is due to noise it may not help to just increase the Ccpc value. Shielding the sensor and the sensor traces may help more in this case. Use constant current / voltage to drive the LEDs, not PWM.

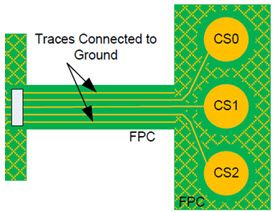

-While designing a PCB for capacitive sensing, a grounded copper plane should be placed surrounding the sensors for good noise immunity. But a solid ground increases the parasitic capacitance of the sensor which is not desired. Therefore, the ground should be filled in a special hatch pattern. A hatch pattern has closely-placed, crisscrossed lines looking like a mesh and the line width and the spacing between two lines determine the fill percentage. In case of liquid tolerance, this hatch fill referred as a shield electrode is driven with a shield signal instead of ground.

Please let me know if the information provided is useful for you.

Best Regards,

David

Hello David,

I have the same problem with PCF8883, It locks up in push button mode. I have even ordered the eval Kit, the kit also locks up. You can try it, if you press for a while.. say 5 sec, it will lock up and stay high.. I need urgent help please, I based my design on this chip in push button mode.

Many Thanks.

Motaz.

Hello,

Once again, thank you all for writing. I am glad to help.

In this case, could you push the sensing distance out as close as possible to make sure it work good then adjust the distance again?

Please review the files attached. The capacitive sensor device has three parameters that influence the switching behavior as shown in the attached FAQs file.

Please let me know your results based on these recommendations.

I hope this information helps.

Regards,

David

It's nice that you want to help, David.

Instead of pointing to generally available documents, that we've probably all read before, perhaps you could address the question we all have: "What causes the sensor to lock up high in pushbutton mode?"

If you had taken the time to read my issues, you'd noticed that it ONLY happens in pushbutton mode. There's no problem in toggle mode or pulsed mode.

Also note that this happens with the Eval kit too.

Please address THAT question.

I suggest you add it to your FAQ.

Hello Stephen,

Thank you very much for writing.

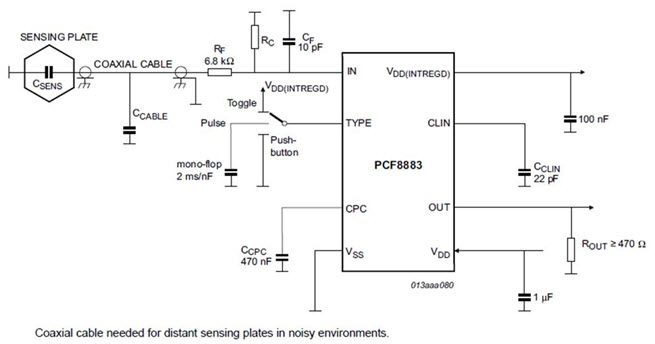

Please find the typical application design with default values below. I recommend using it as a reference for your design.

I hope this information will be useful for you.

If I misunderstood your question, feel free to let me know. I will be glad to help.

Have a great day.

David Diaz.

So, RTFM. Yes, thank you very much, have done that many times, our board is based on this circuit and with the given values.

It this all the "help" we can get from NXP regarding the undocumented lockups and other strange behavior?

I have similar issues. Sometimes it doesn't trigger at all, sometimes it lock up high.

The sensor seems pretty unstable.

After trimming some component values on 3 boards yesterday, I had them all working quite stable. Then this morning, NONE of the 3 boards worked AT ALL!

What's even more odd - yesterday, I noticed that boards that will lock up high, will work perfectly if toggle mode or pulse mode is selected. They will never get stuck in a state.

So, the actual capacitive event is there, but the sensor still will lock up and stay high when in pushbutton mode.

At one point, it was repeatable, that any touch longer than 1 second would cause a lock up, shorter ones were (usually) ok.

Unfortunately, we NEED the pushbutton modes, and a locked up sensor would be a show-stopper.

Would be nice to get some more input on these non-working/lock-up situations.

Getting Flux on the board can influence the circuit. I try not to using flux at all if doing any mods. We implemented a reset circuit to reset if high for longer than some time like 1 second.

Another problem we have is changing the sampling frequency to less than around 1kHz will result in not getting trigger events.