- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- Home

- :

- Product Forums

- :

- Sensors

- :

- Re: Throttle Body Synchronization Using MPX5050

Throttle Body Synchronization Using MPX5050

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi - I'm struggling on how to proceed using FreeScale's MPX5050 sensors for building an Arduino-based Throttle Body Sensor (TBS) for BMW motorcycles. Briefly, a TBS measures the vacuum created by the engine's throttles so that a mechanic can tune/balance the bike's throttles to create equal vacuums during acceleration. A fluid-based manometered TBS is demoed here. Wouldn't a solid state unit be so much better?

While it would be possible to use one (1) MPXV5050VC6T1CT-ND sensors to measure the vacuum of each cyclinder, it would seem more practical to use a dual port MPX such as the MPX7025 series to handle 2 cylinders. So three questions:

1. Does Freescale make a sensor that measures from -50kPa to +50kPa with a 0kPa out at 2.5v? I still need to confirm further but a throttle might create a -50kPa.

2. Is the media resistant gel the only difference between the MPVZ7025DP and the MPXV7025DP? If a motorcycle shop is a greasy messy place, am I better off with a MPVZ unit?

3. In Table 2 on page 3 of the MPX7025 datasheet, there's a maximum pressure for P1 of 200kPa. Is there a maximum pressure for P2? In other words, at what point would I damage this sensor if a bike's cyclinder were to draw X kPa from the P2 port? Is this also 200kPa (or -200kPA on P1)?

Thank you so much.

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Francois,

Motorcycle enthusiast here.

The vacuum level would depend in the specific motorcycle you're using and the size of the engine, some motorcycles are around 30kPa at idle (warm engine). Please notice that ALL pressure sensors measures differential pressure between its pressure ports, hence it wont be possible to use one pressure to sync two _carburetors_ (you won't measure the piston pressure, that's compression pressure not intake manifold pressure, intake manifold pressure should be measured at each carburetor output, which connects to the intake manifold thru the intake manifold boots). So if you plug, let's say pressure sensor port one (P1) into intake manifold one and P2 into intake manifold two, you would be measuring the differential pressure between those two cams which is wrong. The goal of synchronizing your carburetors, is getting the same differential pressure between atmospheric pressure and the output of each carburetor, i.e. stabilize the pressure in the intake manifold. So you would need one sensor per carburetor.

There are some very good projects out there for this application, this one is my favorite:

http://www.instructables.com/id/Arduino-Throttle-Body-Syncronization-Shield/

Regarding your questions:

1. No, the maximum pressure for bi-directional pressure sensor is +-25kPa. However, for this specific application, you do not require bi-directional pressure sensor, the MPXV5050V would be enough:

http://cache.freescale.com/files/sensors/doc/data_sheet/MPXV5050VC6T1.pdf

2. Yes, that's the only difference. However since you're measuring vacuum, you would be fine with standard protection gel because the engine is not "pushing" anything inside the pressure port, is pulling air instead. I personally wouldn't consider a motorcycle shop a "greasy messy place" but if it is, then keep your vacuum meter away from that mess when is not in use :smileywink:.

3. The maximum pressure shown in that table is the differential pressure between P1 and P2 before permanent damage might occur (P1 should be always greater than P2 at any given moment). So you can have P2 at, let's say, 100kPa and have P1 at 300kPa maximum.

Hope it helps.

Josh

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Francois,

Motorcycle enthusiast here.

The vacuum level would depend in the specific motorcycle you're using and the size of the engine, some motorcycles are around 30kPa at idle (warm engine). Please notice that ALL pressure sensors measures differential pressure between its pressure ports, hence it wont be possible to use one pressure to sync two _carburetors_ (you won't measure the piston pressure, that's compression pressure not intake manifold pressure, intake manifold pressure should be measured at each carburetor output, which connects to the intake manifold thru the intake manifold boots). So if you plug, let's say pressure sensor port one (P1) into intake manifold one and P2 into intake manifold two, you would be measuring the differential pressure between those two cams which is wrong. The goal of synchronizing your carburetors, is getting the same differential pressure between atmospheric pressure and the output of each carburetor, i.e. stabilize the pressure in the intake manifold. So you would need one sensor per carburetor.

There are some very good projects out there for this application, this one is my favorite:

http://www.instructables.com/id/Arduino-Throttle-Body-Syncronization-Shield/

Regarding your questions:

1. No, the maximum pressure for bi-directional pressure sensor is +-25kPa. However, for this specific application, you do not require bi-directional pressure sensor, the MPXV5050V would be enough:

http://cache.freescale.com/files/sensors/doc/data_sheet/MPXV5050VC6T1.pdf

2. Yes, that's the only difference. However since you're measuring vacuum, you would be fine with standard protection gel because the engine is not "pushing" anything inside the pressure port, is pulling air instead. I personally wouldn't consider a motorcycle shop a "greasy messy place" but if it is, then keep your vacuum meter away from that mess when is not in use :smileywink:.

3. The maximum pressure shown in that table is the differential pressure between P1 and P2 before permanent damage might occur (P1 should be always greater than P2 at any given moment). So you can have P2 at, let's say, 100kPa and have P1 at 300kPa maximum.

Hope it helps.

Josh

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Josh - this is a huge help. Thank you! And I was inspired by Michael Miller's (Makuna) instructable. He did great work on this project. You're absolutely right that each bike/model will have its own pressures. What kind of bike do you have? Mine's a 2003 R1150R BMW. I've been corresponding with Don Eilenberger who's a big time BMW rider/mechanic Don wrote the Sync DIY that you can read here. Don told me to expect about 30mm of mercury per throttle intake which works out to be about .5kPA. I can loop you into our emails if you're interested and willing to share your email address. Mine is pascalDOTgirardATmeDOTcom. So, on the BMW boxer engines, if I can expect to see 30mm vacuum, a P1/P2 differential sensor (eg MPXV7025) with a port on each side *might* work although I can't always ensure that P1>P2. But can't P2>P1 since we'd see a voltage below 2.5v when P2>P1, right? Can you have P2 at 300kPA and P1 at 100kPA?

Next, it would be good to hit a $40 price point with an atmel ATtiny85 controller, OLED display, the sensor(s), a shield like Makuna's and miscellaneous caps/resistors. I've already built a shield with Eagle similar to Makunas but not yet willing to send it to Silver Circuits until I resolve the sensor question. And at ~$13/sensor, it's more than 50% of the cost.

My MPXV5050VC6T1 sensors arrived today and I'll spend the evening and weekend measuring vacuums on the bike - it's darn cold here in Washington DC.

Thanks again - Pascal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Pascal,

I built a caferacer from a Honda CB550 1974, very fun project.

Correct me if I'm wrong, but your bike doesn't have carburetors (fuel injection?), so you're not building this for your bike, do you?

30mmHg is a very low pressure and is not 0.5kPa. 30mmHg equals to ~4kPa. I think the number is wrong, you probably meant 300mmHg, which equals to ~40kPa, which sounds reasonable for a modern bike.

Regarding the money savings by using only two sensors. That won't work. If you do that, you would be measuring the differential pressure between two throttle intakes, which theoretically speaking should be close to zero (since the vacuum inside the four of them should be equal). While you can adjust the differential pressure between two throttle intakes to be close to zero, you won't be able to adjust the gauge pressure (differential pressure between throttle intake and atmospheric pressure) for each one of them, i.e. both throttle intakes could be at -50kPa, hence you would read a zero differential pressure between them, however they're out of the vacuum range (if they should be at -40kPa).

Rather than sneaking in your conversation with Don, I'd be more than glad to help you use our sensors in your project, just shoot the question and I'll try to answer :smileywink:.

Let me know what are you readings once you get to play with our pressure sensors.

Hope it helps!

-Josh

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hey Josh - I also have an old Honda! It's a 1976 CB360T and is in mint condition. A couple of updates:

1. I misspoke - 30mmg is 4kPA and .5 PSI - I used the wrong unit of measure. :smileyblush:

2. Had some time this afternoon to put my breadboard on the bike. Fun! Hooking up only one cyclinder, it's averaging about 30.66 kPa or 4.45PSI between 1k and 2.5K rpms. The R1150R is fuel injected but BMW does still have a procedure for balancing the throttles by measuring air intake. Fortunately, the same piece of tubing used to connect the sensors works on my bike - no adapters. You were right about total vacuum draw on the bike.

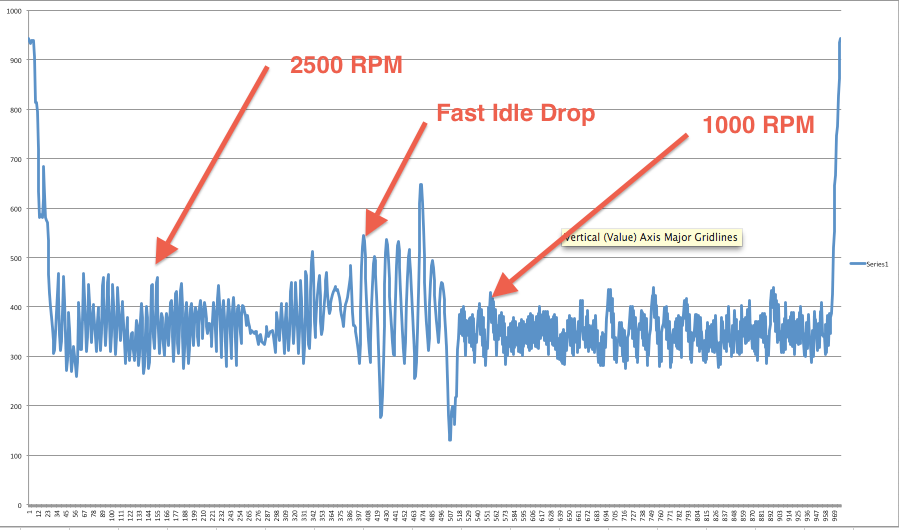

3. I used a running average of 10 samples taken at 1 millisecond intervals to generate the data. As you can see in the chart below, numbers are hovering between 300 and 400 for the most part. The chart's leftside was at 2500RPM and then lowered on the right to 1000RPM. The value 'flopping' in the middle was me dropping the fast idle switch on the bike.

I'd like to get it smoother - maybe it's the bike? Can you tell me if it's worth doing more than 10 samples for a running average? How many should I consider?

Also, would it be worthwhile to use a resistor and different cap as this paper recommends? Makuna didn't use it.

4. I'm still tempted to try a single differential sensor MPXV7025 if there's a way to determine if the sensor can tolerate +100kPa difference in either the P1 or P2 direction. Is there a way to obtain a sample from FreeScale?

Tomorrow if my wife lets me, I'll solder up the right cylinder sensor and test both sides - perhaps even measure the delta. TIA - Pascal

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Pascal,

Old vintage bikes are awesome and bullet proof!. I bought mine from a junk yard, ready to be destroyed, it took me one year and TONS of wife's argues, but now is ready to ride again :smileycool:.

I would recommend you to use a low pass filter as shown in AN1646, ten averaged samples after filtering should be enough to get rid of that noisy signal. I'd recommend you to use the resistor and capacitor shown in that document too.

The MPXV7025 is a bidirectional pressure sensor, which means that you can apply either pressure or vacuum to both ports. However the sensor will measure the differential pressure between P1 and P2 and it can support up to 200kPa. The differential pressure that you'd measure from one intake manifold to another would tend to zero since both pressures should be equal.

Good luck with the wife, that is the hardest part of almost every motorcycle project. :smileywink:

Have fun,

-Josh