- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- RSS フィードを購読する

- トピックを新着としてマーク

- トピックを既読としてマーク

- このトピックを現在のユーザーにフロートします

- ブックマーク

- 購読

- ミュート

- 印刷用ページ

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

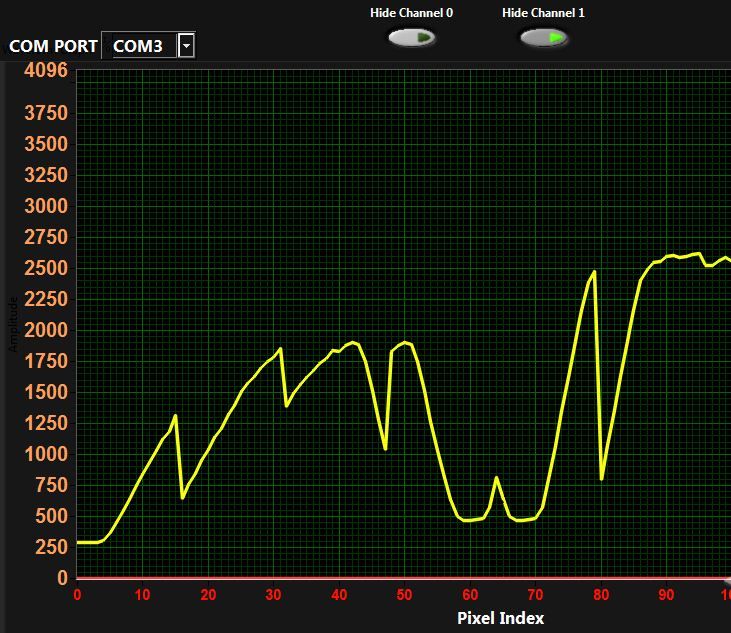

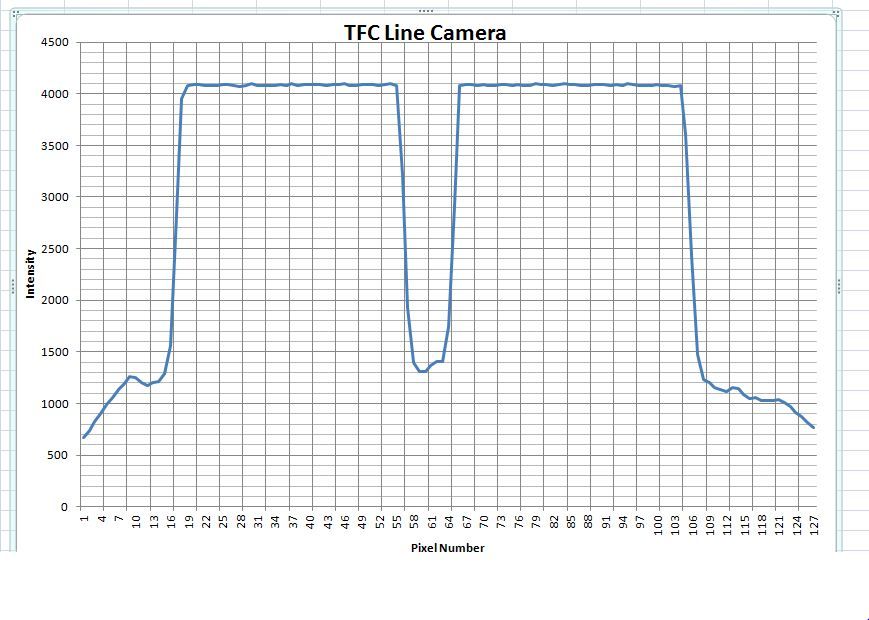

I have discovered a few issues with the camera and the latest FRDM-TFC (perhaps I have a bad one). [And yes, I did cover the back of the camera PCB since light bleeds through the PCB into the array (also mentioned in ProTip #1 Line Scan Camera Use)

1. The sample rate of the camera data is too slow (1 Hz or so). I estimated the 1 Hz by watching the led lights change and seeing labview updates.

2. My particular camera seems to be off by 20 degrees (I have to point it to the right by 20 degrees or so to get it to show up in the middle of the labview (see attachment). I wonder if this might be a poorly mounted array or perhaps misaligned lens? I will ask John if I can try another one.

解決済! 解決策の投稿を見る。

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Ok. Thx for the above replies. Turns out that my camera is fine. Thx to David for offering to scope the camera for me at lunch today. My issue must have been due to sampling issue using the ADC code etc... I was just jumping the gun and wanting to see the camera output now that I have my car all put together.

My son and I are having a blast with this !

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Jeffrey,

You may want to adjust the focus on your camera as well. The dips should look nice and square.

Daniel

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Daniel,

Yeah, my focus was off. thx.

I had not looked at the code in detail as I had just assumed it was verified and checked in and matched the CW code. I got rid of the inner j loop and it works better,

BTW, the code is capturing camera data from one camera, but it uses double buffering TFC_LineScanImage0, and TFC_LineScanImage1.

Here are some other differences/observations:

- Both don't properly print the TFC_LineScanImage1 properly

- The mbed code does not include the TFC_SetLineScanExposureTime routine that the CW code has.

- The CW code uses the PIT timer to initiate the camera line scan. The mbed code uses the servo TPM. Thus, there is a scheduling difference between the codes.

- The camera capture is not as fast in mbed versus Code Warrior. This is probably configurable with timers and such, but just an observation.

Regarding using Excel versus Labview, that is a good idea, however, I prefer the realtime display. I think Eli mentioned something about a free graphical processing alternative.

Jeff

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

I was wrong. I thought TFC_LineScanImage1 was the double buffer. But it turns out that it is for the 2nd camera as you suspected. There are 3 videos that talk about his google code.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

I guess I saved myself a whole lot of grief by not even attempting to use the line sensor code...

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Wasn't a big deal-- just saw the "has issues..." comment and thought the bugs were intentional. But having scope data to tell me something was wrong was key. Will try to check in update in mbed soon.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Update made in mbed-- up to 4.0 on the library now which has the fixes.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Thx. Just curious. Do you have a summary of the changes you had to make?

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

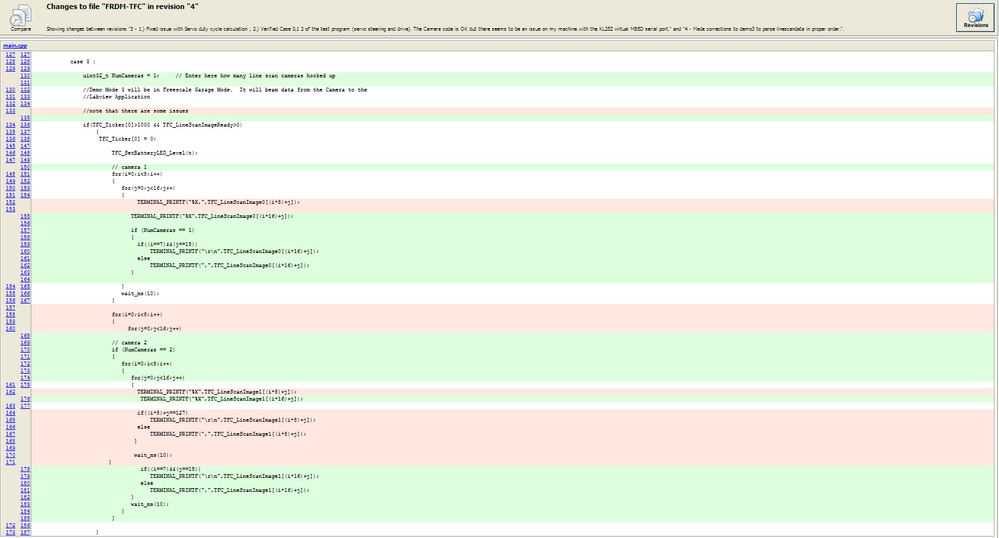

1) make # cameras an option so it doesn't run second set of loops if only 1 camera

2) fix '8' to '16' everywhere (i*16+j)

3) put in end of line stuff for first camera (if there is only 1 camera).

4) condition for end of line made to be ((i==7) && (j==15))

If you want code diffs- just check out library as separate thing in mbed and you can do version compare between 3 and 4 (file revisions...)

Here is the diff screenshot:

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

For the mbed code, I was wondering what frequency the servo should be run since the camera exposure time is based on the servo frequency (unlike the CW code).

Here is a comparison of MBED code and CW:

| MBED | Code Warrior | |

| Trigger for ADC Hander | TPM1 | PIT running at 20 Hz or 50 ms |

| TPM0(Motors) | 4000 Hz or 0.25 ms | 5000 Hz or 0.2 ms |

| TPM1(Servo) | 50 Hz or 20ms | 50 Hz or 20ms |

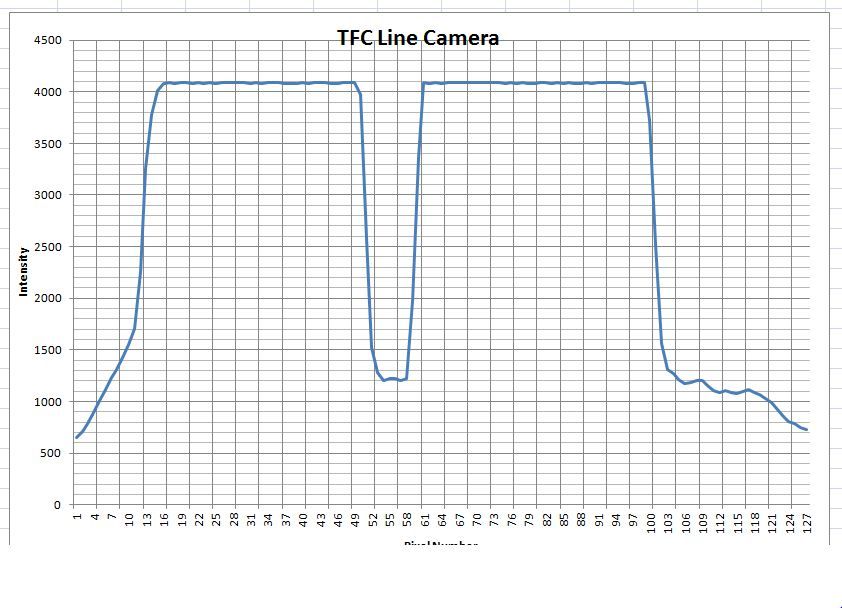

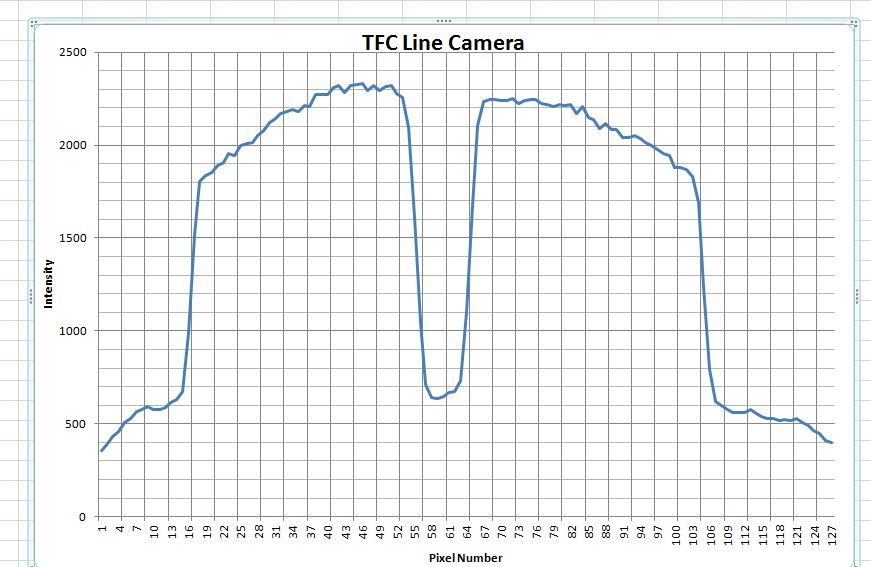

Attached are camera captured data where I used Eli's terminal printf to an excel program on the fly (my alternative to the expensive Labview).

CodeWarrior with camera capture at 20Hz:

Default MBED code with camera capture at 50Hz:

Default MBED code with camera capture at 20Hz:

Notice that there is a lot more light intensity and the edges are much, much sharper when the servo frequency is decreased.

Here is my question:

Why is the MBED running the capture so fast and why is the CodeWarrior code using the PIT instead of the TPM1 to do the ADC handler?

And what frequency should we be running the servo?

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

hello sir,

can you please describe the way to capture the data from camera the way you have done.

i have NI Labview but its not working.

then i switched to putty terminal but it shows data only not graphically.

can you tell me how to plot the graph of data ??

Thank you

Azaj Vahora

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

I need to design some lights myself. My son and I made an oval paper track this past weekend. It covers our living room (my wife hopes it is temporary. lol). I have been messing with a steering PID controller trying to get the right parameters to keep the car on the track at speed. I am not going to be able to make it tomorrow as I have a lunch appointment. But I will probably come the following Monday. - Jeff

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

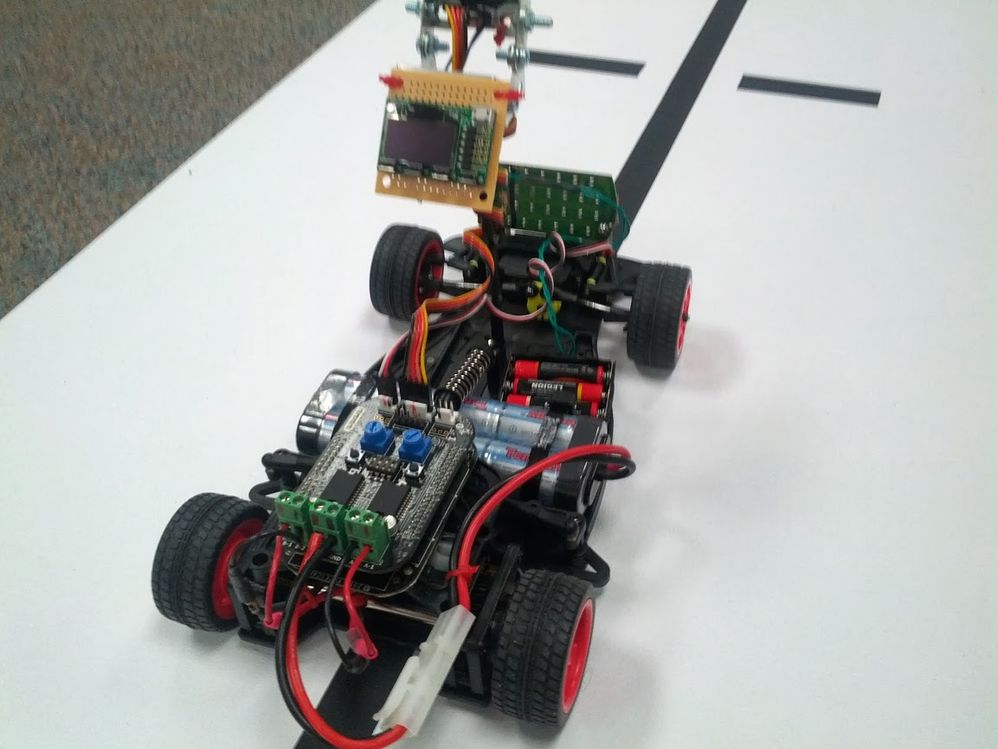

I can give you a tip: got a $3 flashlight from Harbor Freight that has over 24 leds in it with batteries! Hacked it apart and mounted it.

Daniel

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Assuming you connected directly to battery, did you use current limiting registers or a LM317 regulator/(POT or PWM) for the mounted lights?

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

I brought over the battery from the flashlight as well. The lights have 'dark patches' so I plan to remove them from the PCB that came with the flashlight to mount them myself.

That said, supposedly a good line processing algo doesn't need good lighting :smileywink:

Here's a pic of my car showing the lights in front with separate battery pack. Note the o-scope mounted on the camera mast to review camera data.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Very cool picture of your car!

I did not realize you brought the battery pack with it. I actually wired mine into the main regchargeable battery hence my question.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Jeffrey,

Another tip-- don't use the "I" in the PID. The steering servo already had integration built-in... Most you should do is PD ;-)

I made a paper track as well in the living room. Wife doesn't seem to mind... yet.

Daniel

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Daniel,

Regarding the PD tip above, thanks. I was doing a PID even though the steering servo has one too because lecture #4 of the 5 part lecture from India by Prof. Umanand implied it. However, I am guessing that there is a problem with the lecture. At the end of the lecture, it also indicates that the speed does not seem to feed into the steering control. I don't see how this is correct.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

I recall Prod. Umanand saying that double integration control was bad (has to do wtih . Servos have integration built in by definition (at least from what he's saying). Any motor control is ultimately speed control (as motor speed is what is proportional to voltage).

My understanding from the lectures was that the current speed of the servo motor is sensed, integrated to get position, and that "actual position" compared against the 'target position' given from outside the servo to determine the error. The error is then used with some factory set KI parameter to determine the new speed of the servo motor.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Yes, he says double integration is bad - in fact in lecture #3 at the beginning he has a PD controller and middle of lecture #4. However, at the end of lecture #4, he replaces it with a PID (see the green I in the slide). Very confusing to me.