- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- MCUXpresso Training Hub

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

-

- Home

- :

- Product Forums

- :

- Sensors

- :

- Re: Question, how to measure the accuracy of MMA8451Q ODR

Question, how to measure the accuracy of MMA8451Q ODR

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dear team,

I would like to ask about ODR accuracy of MMA8451Q.

My customer has a doubt on the accuracy of ODR(+-2%) from their test.

The customer’s test is as below.

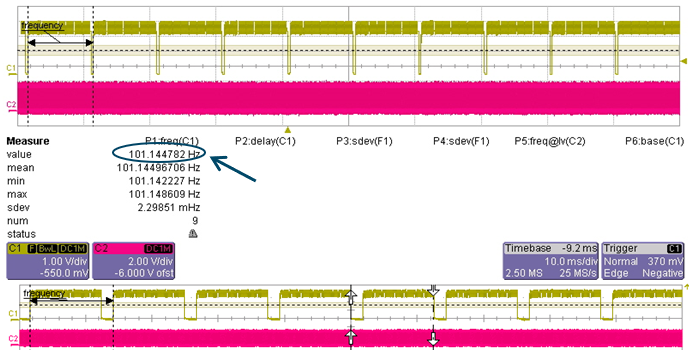

- Set up the ODR=100Hz by register.

- Set up the interruption from MMA8451Q when FIFO contains 16 data.

- MMA8451Q will issue the interruption with 160mS period.

As a result, they saw the interruption period from MMA8451Q could exceed from +-2%.

Is their test procedure is correct for ODR accuracy measurement?

Could you show me how to measure the ODR accuracy?

Best Regards,

Miyamoto

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Miyamoto-san,

Here is what I received from the product group:

The min max 4 sigma value is expected to be +/- 10%.

The best way is to measure using a DRDY interrupt as you mentioned. Measure the timing between them.

You can also use one of our kits (Sensor board + MCU) and our tools log data with timestamp. That can be the quickest way to get timestamp too.

It should be much better than 2% assuming no major temperature extremity.

We don’t have any data on aging accuracy but I don’t see it deviating more than +/- 10%.

Best regards,

Tomas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello TomasVaverka

Thanks for your support!

Could you show me what sigma values that the +/-2% of the typical value is?

Regards,

Miyamoto

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello TomasVaverka

> We don’t have any data on aging accuracy but I don’t see it deviating more than +/- 10%.

The customer thinks that semi-conductor will not degrade then it will not be deviating more than +/- 10%. Right?

If so, do you have any documentations which can back up that?

Regards,

Miyamoto

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Miyamoto-san,

As mentioned before there are no documents about aging accuracy available.

Best regards,

Tomas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello TomasVaverka

Thanks for your reply!

How about the sigma number of the +/-2% typical value?

Regards,

Miyamoto

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Miyamoto-san,

I do not quite understand this question. The percentage should simply be a % of the ODR chosen. 2% of ODR 100 Hz should mean an expected deviation 2 Hz.

If this does not answer your question, please let me know.

Best regards,

Tomas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello TomasVaverka

You informed me about the MAX value is related to 4 sigma.

So the customer asked me that what sigma value is related to your typical +/-2%.

In my understanding, the sigma value is deeply related to the deviation in the viewpoint of statistics.

Regards,

Miyamoto

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Miyamoto-san,

Please find below what I got from our product group:

The min max 4 sigma value is expected to be +/- 10%. So, 1 sigma is basically 2.5% of ODR. That is the typical deviation. So, ODR +/- 2.5% is the typical ODR deviation (1 sigma).

4 sigma (10%) is the max you could get based on the oscillator.

Best regards,

Tomas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Dear Miyamoto-san,

Please note that ±2% is a typical value at 25 °C.

Although customer’s method makes sense, I would recommend a simpler technique without using the FIFO. Just select the ODR, enable the data ready interrupt (INT_EN_DRDY = 1), route it either to INT2 or INT1 (INT_CFG_DRDY = 0 or 1) and then measure changes on the selected INTx pin. .

I hope it helps.

Best regards,

Tomas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Miyamoto-san,

I do apologize for the delay, I am double checking it with the product group and should have an answer by the end of this week.

Best regards,

Tomas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello TomasVaverka

Thanks, I will wait.

Please show me the MAX, MIN and aging of ODR accuracy.

Regards,

Miyamoto

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Miyamoto-san,

Here is what I received from the product group:

The min max 4 sigma value is expected to be +/- 10%.

The best way is to measure using a DRDY interrupt as you mentioned. Measure the timing between them.

You can also use one of our kits (Sensor board + MCU) and our tools log data with timestamp. That can be the quickest way to get timestamp too.

It should be much better than 2% assuming no major temperature extremity.

We don’t have any data on aging accuracy but I don’t see it deviating more than +/- 10%.

Best regards,

Tomas

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello TomasVaverka

Thanks.

> Please note that ±2% is a typical value at 25 °C.

From below community thread, I understand that +2% is the Max.

Not true?

https://community.nxp.com/thread/436100

Please let me know the maximum value.

Anyway I will inform the customer the method you gave to me.

Regards,

Miyamoto