- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- RSS フィードを購読する

- トピックを新着としてマーク

- トピックを既読としてマーク

- このトピックを現在のユーザーにフロートします

- ブックマーク

- 購読

- ミュート

- 印刷用ページ

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

We did buy FRDM_64F freedom board with 3 axis gyro, 3 axis accelerometer, 3 axis magnetometer. but USB not being detected on this board due to some problem as per my colleague and i cannot use it right now.

So i ported this code into DSP controller TMS320F28335. When i am doing precision accelerometer calibration as per AN5286 using 4 para, 7 para calibration, i feel i got the correct calibration gain parameters since, inverse Gain matrix diagonal values are nearer to 1 (but x,y,z offset para are very less 0.000xx).

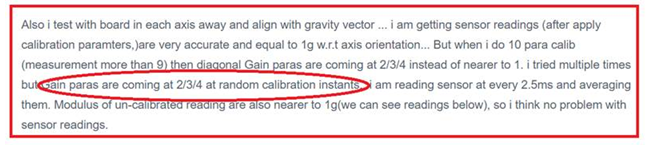

Also i test with board in each axis away and align with gravity vector ... i am getting sensor readings (after apply calibration paramters,)are very accurate and equal to 1g w.r.t axis orientation... But when i do 10 para calib (measurement more than 9) then diagonal Gain paras are coming at 2/3/4 instead of nearer to 1. i tried multiple times but Gain paras are coming at 2/3/4 at random calibration instants.. i am reading sensor at every 2.5ms and averaging them. Modulus of un-calibrated reading are also nearer to 1g(we can see readings below), so i think no problem with sensor readings.

the changes i have done:

i am using XYZ data address at 0x33 (at 0x39 accelerometer reading comes) instead of 0x01 address so that magnetometer + accelerometer reading can be taken without changing the address inbetween (i2c address increment automatically.) and also i will get the directly right justified 16 bit data (no need to convert left shifted 16 bit data to 14 bit data). I changed setting 4g to 8g with sensitivity 1024. of course i tried with 4g setting (by correcting sensitivity to 2048(existing 8192) as i am using right justified accelerometer data) also but same problem with 10 para calibration.. diagonal gain parameters are no where nearer to 1.

I'm printing the below raw 12 averaged reading of accelerometer which i have used for calibration.. .

meas1 = (-0.0134082027, -0.0690478459, 0.966635764)

meas2 = (0.0177197251, 0.0200390629, -1.0054394)

meas3 = (-0.0132861324, -1.0000824213, -0.0650292933)

meas4 = (0.0158447269, 0.99924314, 0.028500976)

meas5 = (1.02742672, -0.0213916004, -0.0155908205)

meas6 = (-1.01027834, 0.00377929676, -0.0351611301)

meas7 = (-0.0197656248, -0.546865225, 0.811196268)

meas8 = (-0.0207958985, -0.745546877, 0.642041028)

meas9 = (-0.0193212889, -0.893725574, 0.433476567)

meas10 = (-0.00514160143, 0.446332991, 0.862988293)

meas11 = (-0.000698242162, 0.661806643, 0.719794929)

meas12 = (0.00429687509, 0.835830092, 0.523242176)

these readings are taken with 12 different orientation including standard each axis way and align gravity and other 6 reading with board +- 30, +- 45, +60 orientation. i have check the same algorithm in GNU Octave platform(similar to Matlab) and given above reading as input, then it showing an error that Inverse matrix elements are imaginary number where as offset parameters almost same as that of DSP software output.

So i really stuck with this problem...

So please anyone suggest me where i have gone wrong...

Also is it possible to check 10 parameters calib with above readings using FRDM_64F Freedom board or any uC board, to cross check the same problem is being repeated with above reading or not?

解決済! 解決策の投稿を見る。

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Venkat,

The calibration algorithm performs a best fit of the measured data points to a 3D conic surface.

Usually this 3D surface shall be an ellipsoid but as your data set (i.e. sensor positions) is not quite well chosen, the algorithm actually yields another type of conic surface (paroboloid or hyperboloid), hence the surprising diagonal elements and complex numbers.

You can keep the first 6 orientations (faces of a cube) but the additional ones shall be more "equally" spread over all possibilities (of the 3D sphere). In your case, the X axis is about 0g for all last 6 positions, you simply need to select more diverse orientations as illustrated in the provided screen shots of the Sensor Fusion Toolbox GUI.

Regards, Jacques.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Thank you very much for your information.

When i calib for 4 parameters calibration(measurement >= 4), 7 parameters calibratation (measurement >= 6) ... i found no issue since i am getting diagnal elements of Inverse Gain matrix are close to 1.

But when i extended measurement to >=9.. i am getting diagnal elements of inverse gain matrix are 2.x / 3.x etc...

Below are the measurement taken in sequence for 4,7,10 para calib...

meas1 = (-0.0134082027, -0.0690478459, 0.966635764)

meas2 = (0.0177197251, 0.0200390629, -1.0054394)

meas3 = (-0.0132861324, -1.0000824213, -0.0650292933)

meas4 = (0.0158447269, 0.99924314, 0.028500976) --- Execution of 4 para calib

meas5 = (1.02742672, -0.0213916004, -0.0155908205) --- Execution of 4 para calib

meas6 = (-1.01027834, 0.00377929676, -0.0351611301) --- Execution of 7 para calib

meas7 = (-0.0197656248, -0.546865225, 0.811196268) --- Execution of 7 para calib

meas8 = (-0.0207958985, -0.745546877, 0.642041028) --- Execution of 7 para calib

meas9 = (-0.0193212889, -0.893725574, 0.433476567) --- Execution of 10 para calib

meas10 = (-0.00514160143, 0.446332991, 0.862988293) --- Execution of 10 para calib

meas11 = (-0.000698242162, 0.661806643, 0.719794929) --- Execution of 10 para calib

meas12 = (0.00429687509, 0.835830092, 0.523242176) --- Execution of 10 para calib

Can you try 10 parameter calibration on these above measurements? (may be editing the fGsStored[] during debugging). Upto 8 measurments i am getting gain elements of Inverse matrix close to one. But when i am taking 9th measurement the gain elements of Inverse matrix are 2.x /3.x randomly.

I feel there is no problem with sensor reading since Mod of these sensors reading close to 1. Am i right?

I implemented this 10 para calib algorithm in Octave (equivalent to Matlab) and applied above 12 measurements then it is generating complex number for Inverse gain matrix...

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi Venkat,

The calibration algorithm performs a best fit of the measured data points to a 3D conic surface.

Usually this 3D surface shall be an ellipsoid but as your data set (i.e. sensor positions) is not quite well chosen, the algorithm actually yields another type of conic surface (paroboloid or hyperboloid), hence the surprising diagonal elements and complex numbers.

You can keep the first 6 orientations (faces of a cube) but the additional ones shall be more "equally" spread over all possibilities (of the 3D sphere). In your case, the X axis is about 0g for all last 6 positions, you simply need to select more diverse orientations as illustrated in the provided screen shots of the Sensor Fusion Toolbox GUI.

Regards, Jacques.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi,Thank you so much for your reply and it helps me a lot.

I think your observation is correct and due to X axis near to zero in last measurements, the algorithm giving another type of conic surface (paroboloid or hyperboloid) instead of sphere.

first 6 readings i have taken as you mentioned... face of cube..... that means.. X axis away from gravity(+90) and aligned (-90 deg) gravity and repeated same for remaining Y,Z.

After that i couldn't read orientations illustrated in the provided screen shots of the Sensor Fusion Toolbox GUI so i have taken different orientation (Y axis - 30,45, 60, 120, 135, 150.).

Can you please suggest me the Orientation (X axis, Y axis, Z axis angles) to be kept for rest of 6 measurement.?

Once again, Thank you so much for your reply...

Regards,

Venkat.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hello,

Exact orientations are not critical (that's the benefit of the sphere fitting algorithm), they simply need to be significantly different from each others. Just add a mix of rotations (3 + 3) vs both X and Y axes.

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi,

As for your first issue with the FRDM-K64F not being detected, please follow the instructions here OpenSDA Serial and Debug Adapter | NXP and here DAPLink bootloader update | Mbed.

Regarding the calibration, I will let amitpurohit comment about it.

Best regards,

Tomas

- 新着としてマーク

- ブックマーク

- 購読

- ミュート

- RSS フィードを購読する

- ハイライト

- 印刷

- 不適切なコンテンツを報告

Hi,

Please see below Amit's response.

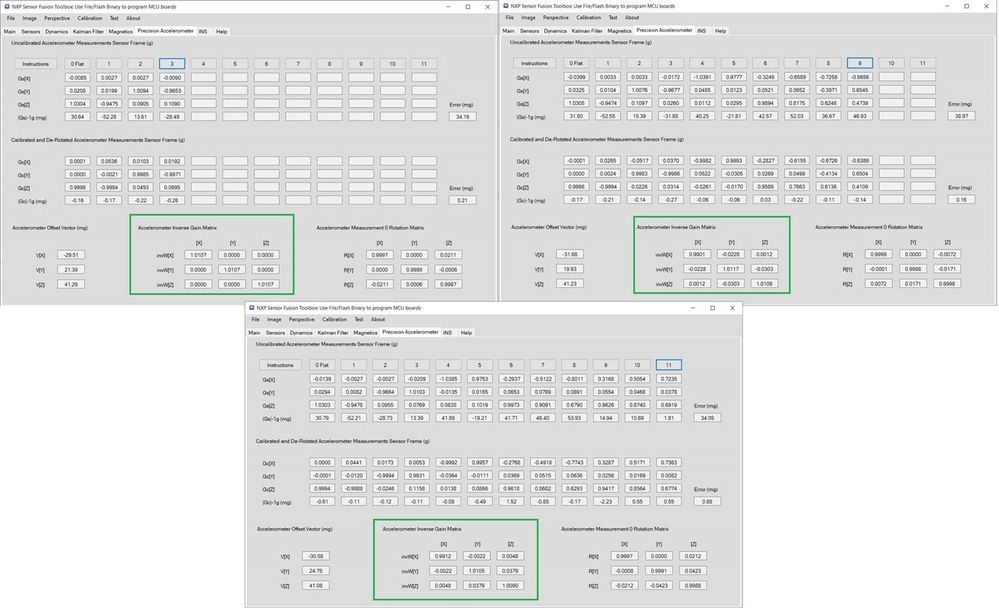

I tried performing 12-point calibration multiple times using FRDM-K64F-AGM01 having FXOS8700 on Sensor Fusion toolbox and not able to create reported scenario (for quick reference providing below snapshot of issue reported):

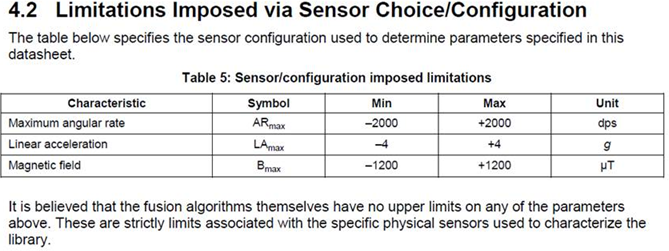

I would recommend checking the sensor register configuration used in your setup. Also see following sensor configuration limit as suggested by sensor fusion design spec document:

Providing you below snapshot of my trials (with 4-point, 10-point, 12-point calibration) at my end (you can see that the acceleration inverse gain matrix diagonal values are always near to ~1).

Best regards,

Tomas