- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- Home

- :

- Model-Based Design Toolbox (MBDT)

- :

- Model-Based Design Toolbox (MBDT)

- :

- Re: pmsm rotor alignment

pmsm rotor alignment

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

I am trying to run a motor prototype with the modified version of the pmsm closed loop example. I want to know what happens during the alignment sequence. When i start the code by pressing the sw1 button , the execution starts and the motor shaft rotates a bit then stops and draws a large amount of current.

I changed the polepair values and current limits and the other parameters.Is there something else i should change to get the rotor align process working. ps i havent changed the pi tuning according to the motor i m using . will that affect the align process.

Thank you.

#MBDT

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Sriram,

Since there are multiple unknowns about your hardware and motor setup, i suggest having them better understood and modify the model parameters I have told you previous.

Increase the Voltage and Current limits and all the other needed parameters, take a good look at all the parameters and apply the correct values for each.

Also update the model from the latest Toolbox release 4.3.0, to update/add the block check_range:

Please read carefully this and my other replies and apply the suggestions to your model.

Have a good day!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello stefanvlad ,

Thanks for the reply. I went through the speed control module. I am modifying the pmsm closed loop example from the nxp blockset s32k144 examples. But here in the example file there is no separate speed or torque control modes available. If i want to run a 120V motor with a rated current of 100 A what parameters should i change apart from the no of poles and pi values of speed and current controller.

And how to choose the Iq and Id reference. Are these values in per unit basis or is it actual value . Attached the base model we are working with. This model was sent by adrian tudor from nxp since we had some issues running the default example model.

Thank you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Sriram,

I have looked into your attached model, but it seems there are no modification from the standard model and also it is an older version of the model. We have made some updates for it. I do recommend downloading the latest 4.3.0 Toolbox from: NXP Model-Based Design Toolbox for S32K1xx MCUs - ... - NXP Community

Also, what kind of motor are you using? and what hardware for invertor and all details

Since the model we provide is designed to work on the Kit we deliver: S32K144 BLDC/PMSM Development Kit | NXP Semiconductors. It has 12V power supply and not 150V. This is a problem since you will need to rescale a lot of variables for the control system to work with this High Voltage.

First download latest Model-Based Design Toolbox for S32K1xx – version 4.3.0

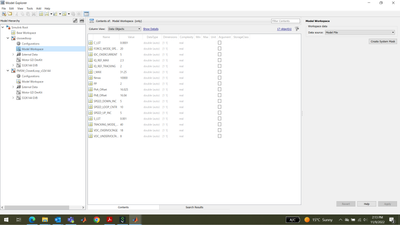

Then you will need to modify parameters from Model Explorer:

You will need to modify all those parameters for a motor running 150V with 100A.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello stefanvlad,

We are using IPMSM rated for 120V and a inverter which is rated upto 240V 100A. We are planning to test the closed loop model by running the motor at 120V.

I have sent you the modified model we made in private chat. We replaced the hall sensor based positioning with the sine cosine encoder measurement . Current measurement will be done by hall sensors.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello stefanvlad,

We are using a separate IPMSM motor rated for 350V and the inverter specs are 240v 100A.We modified some parameter from the base model i sent you earlier. sending you the modified model in private chat.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Sriram,

Since there are multiple unknowns about your hardware and motor setup, i suggest having them better understood and modify the model parameters I have told you previous.

Increase the Voltage and Current limits and all the other needed parameters, take a good look at all the parameters and apply the correct values for each.

Also update the model from the latest Toolbox release 4.3.0, to update/add the block check_range:

Please read carefully this and my other replies and apply the suggestions to your model.

Have a good day!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Sriram,

Have you looked into the article Module 8: Speed Control - NXP Community check Fig. 31: Rotor Position Conditioning?

It is normal for the motor to draw a large current during the alignment phase, as this will block the motor shaft with that high current, making a standstill of the rotor.

Then the motor control code will start open loop phase, and have a start-up ramp, increasing the speed until it reaches 400 RPM and then it will go to closed loop, using the Hall sensors to read the motor speed and correct the speed loop.

This should help a bit more,

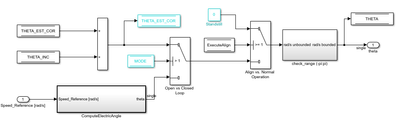

Look in PMSM_ClosedLoop_s32k144/S32K144 EVB/SlowLoopControl/Alignment_vs_NormalOp_Sequence

There are 2 constant blocks: Torque Reference for Alignment (iQ-ref) and Flux Reference for rotor alignment (iD-ref). They will impose the values for currents during the alignment phase.

You can modify these values a bit but be careful and do not increase too much these values.

Hope this helps you