- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- Home

- :

- Product Forums

- :

- 8-bit Microcontrollers

- :

- Re: MC9S08QD2 different timing in test and production

MC9S08QD2 different timing in test and production

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

MC9S08QD2 different timing in test and production

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

I have a problem with my software timing. I've got a PCB with the MC9S08QD2. For developping the software for this I reprogrammed the device with P&E Cyclone Pro.

Now the PCBs are programmed for serial production by an external supplier and we found that the timing doesn't fit any more, the processor works slower.

I don't understand this behaviour because in the main the internal clock is initialized with

ICSC1 = 0x07;

ICSC2 = 0xC0;

TPMSC = 0x4F;

TPMMOD = 0x0005;

Is there any possibility to overwrite this by programming?

Is there any configuration I should keep in mind?

Thanks for your help,

Marion

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I believe you use the internal clock (based on you ICSC1 setup).

For accurate timing an accurate (and usually different) trim value needs to be programmed for each and every MCU.

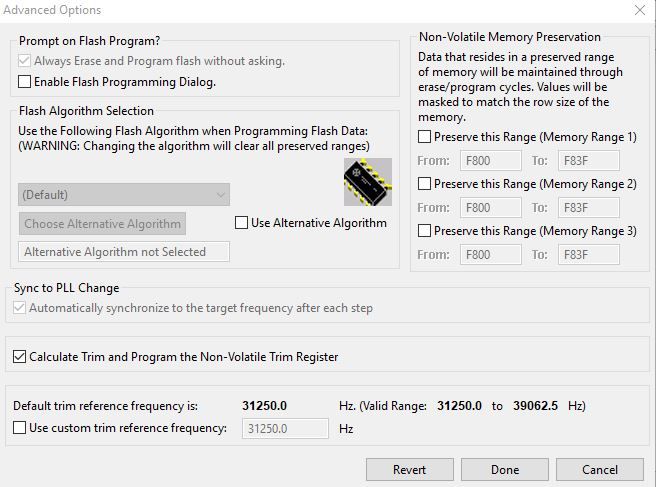

Cyclone does this automatically but perhaps your programming service doesn't, or has a different assumption about what the operating frequency is.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Marion,

Tony is correct about the trim value that needs to be programmed on each MCU. NXP stores an 8-bit trim value for the ICS at location 0xFFAF in flash on our production line. The fine trim bit (FTRIM) is stored in bit 0 of the 0xFFAE. These locations are erased during a production programming process, so the programming tool must know to read them before erasing, and then program them after the application code is programmed. The Cyclone Pro defaults to calculating the trim value and then programming it after the app is programmed. This can be seen in the Advanced Programming Options in one of the Cyclone Pro windows. You can uncheck the Calculate Trim box, and the Cyclone Pro will copy the value that NXP programmed to re-program that value after the flash is erased and programmed with the app code. However, it is always best to calculate the trim value in the application because this is more accurate (accounts for the system parasitics).

A generic programmer that does not check for the trim values will erase all flash and only program the app code. Our trim value will be lost. (0xFF, the value of an erased location, will cause the ICS to run slower if this is used as the trim value.) There are production programmers that can read the NXP factory trim values, but this is usually an option that the program house or test engineer needs to enable.

Please make sure that your code reads the 0xFFAF location and stores the data to the ICSTRM register, and then reads the 0xFFAE location and stores bit 0 to the ICSSC register. Otherwise, the internal oscillator will use a default trim value of 0x80 which may not give you the frequency you desired.

Regards,

John Suchyta

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello John,

thanks for this detailed answer,

I hope I'll solve my issue with this!

Regards,

Marion

2018-09-13 18:38 GMT+02:00 jsuchyta <admin@community.nxp.com>:

NXP Community

<https://community.freescale.com/resources/statics/1000/35400-NXP-Community-Email-banner-600x75.jpg>

Re: MC9S08QD2 different timing in test and production

reply from John Suchyta

<https://community.nxp.com/people/jsuchyta?et=watches.email.thread> in *8-bit

Microcontrollers* - View the full discussion

<https://community.nxp.com/message/1057071?commentID=1057071&et=watches.email.thread#comment-1057071>