- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- MCUXpresso Training Hub

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

-

- Home

- :

- i.MX Forums

- :

- i.MX RT Crossover MCUs

- :

- Some questions in the PWM project ?

Some questions in the PWM project ?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi,

When reading the PWM project, I have some questions:

(1)What does the following code do? Some people say they are trying to turn off the fault protection? If so, I want to know how do they work?

/* Set the PWM Fault inputs to a low value */

XBARA_Init(XBARA1);

XBARA_SetSignalsConnection(XBARA1, kXBARA1_InputLogicHigh, kXBARA1_OutputFlexpwm1Fault0);

XBARA_SetSignalsConnection(XBARA1, kXBARA1_InputLogicHigh, kXBARA1_OutputFlexpwm1Fault1);

XBARA_SetSignalsConnection(XBARA1, kXBARA1_InputLogicHigh, kXBARA1_OutputFlexpwm1234Fault2);

XBARA_SetSignalsConnection(XBARA1, kXBARA1_InputLogicHigh, kXBARA1_OutputFlexpwm1234Fault3);

(2)What's the difference between signed center-aligned and unsigned cente-alignes ?

(3)What's the difference between signed edge-aligned and unsigned edge-aligned ?

/*! @brief PWM operation mode */

typedef enum _pwm_mode

{

kPWM_SignedCenterAligned = 0U, /*!< Signed center-aligned */

kPWM_CenterAligned, /*!< Unsigned cente-aligned */

kPWM_SignedEdgeAligned, /*!< Signed edge-aligned */

kPWM_EdgeAligned /*!< Unsigned edge-aligned */

} pwm_mode_t;

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello ,

Hope you are doing well.

(1)What does the following code do? Some people say they are trying to turn off the fault protection? If so, I want to know how do they work?

The intended application of the Inter-Peripheral Crossbar Switch (XBAR) module is to provide a flexible crossbar switch function that allows any input (typically from external GPIO or internal module outputs) to be connected to any output (typically to external GPIO or internal module inputs) under user control. This is used to allow user configuration of data paths between internal modules and between internal modules and GPIO. With that code you are setting the PWM channels to a positive logical level, this way when the trigger condition of the PWM occurs the channel will go to a High State. If you comment these lines then when the trigger condition of the PWM occurs nothing will happen, the channel will stay on the same logical level. Please refer to this thread for more details PWM on i.MX RT 1050 EVKB.

(2)What's the difference between signed center-aligned and unsigned center-aligned ?

This is an example of a center aligned PWM signal. The signed range of integer values that can be stored in 16 bits is −32,768 (−1 × 215) through 32,767 (215 − 1); the unsigned range is 0 through 65,535 (216 − 1).

(3)What's the difference between signed edge-aligned and unsigned edge-aligned ?

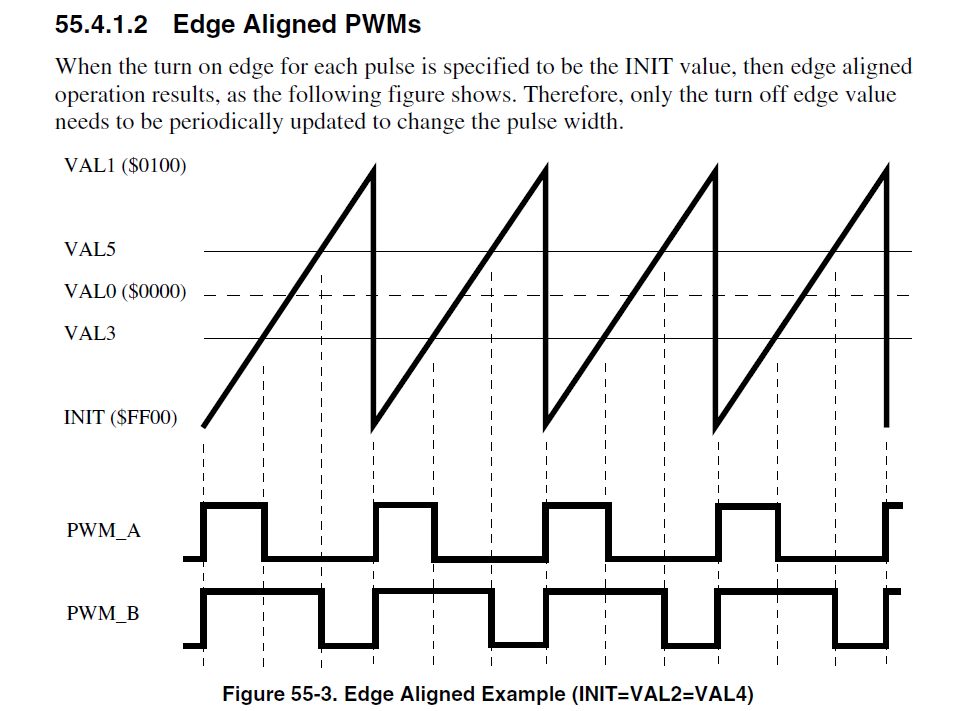

The difference is the same as the above answer. Please see the image for an example of edge aligned signals.

Please refer to reference manual for further details on the PWM.

Hope it helps!

Sabina

-----------------------------------------------------------------------------------------------------------------------

Note: If this post answers your question, please click the Correct Answer button. Thank you!

-----------------------------------------------------------------------------------------------------------------------

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello ,

Hope you are doing well.

(1)What does the following code do? Some people say they are trying to turn off the fault protection? If so, I want to know how do they work?

The intended application of the Inter-Peripheral Crossbar Switch (XBAR) module is to provide a flexible crossbar switch function that allows any input (typically from external GPIO or internal module outputs) to be connected to any output (typically to external GPIO or internal module inputs) under user control. This is used to allow user configuration of data paths between internal modules and between internal modules and GPIO. With that code you are setting the PWM channels to a positive logical level, this way when the trigger condition of the PWM occurs the channel will go to a High State. If you comment these lines then when the trigger condition of the PWM occurs nothing will happen, the channel will stay on the same logical level. Please refer to this thread for more details PWM on i.MX RT 1050 EVKB.

(2)What's the difference between signed center-aligned and unsigned center-aligned ?

This is an example of a center aligned PWM signal. The signed range of integer values that can be stored in 16 bits is −32,768 (−1 × 215) through 32,767 (215 − 1); the unsigned range is 0 through 65,535 (216 − 1).

(3)What's the difference between signed edge-aligned and unsigned edge-aligned ?

The difference is the same as the above answer. Please see the image for an example of edge aligned signals.

Please refer to reference manual for further details on the PWM.

Hope it helps!

Sabina

-----------------------------------------------------------------------------------------------------------------------

Note: If this post answers your question, please click the Correct Answer button. Thank you!

-----------------------------------------------------------------------------------------------------------------------

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

The crossbar has to be set up to get the fault inputs in the correct state else they inhibit the PWM output, that cuaght me out at first. You can get round it if you dont want the fault inputs. You can get round that by configuring the fault handling on the PWM channel and in that case you dont need to configure the crossbar, something like this:

pwm_fault_param_t faultParam;

PWM_Type *base = BOARD_PWM_BASEADDR;

// disable the fault inut monitoring

base->SM[kPWM_Module_3].DISMAP[0] = 0;

base->SM[kPWM_Module_3].DISMAP[1] = 0;

faultParam.faultClearingMode = kPWM_Automatic;

faultParam.faultLevel = true;

faultParam.enableCombinationalPath = false;

faultParam.recoverMode = kPWM_RecoverHalfAndFullCycle;PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_0, &faultParam);

PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_1, &faultParam);

PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_2, &faultParam);

PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_3, &faultParam);

Hello,

I found that just the following two lines of code can also set the PWM output correctly.

PWM_Type *base = BOARD_PWM_BASEADDR;

base->SM[kPWM_Module_3].DISMAP[0] = 0;

So, I wonder if any other code is necessary in the example you gave.

pwm_fault_param_t faultParam;

base->SM[kPWM_Module_3].DISMAP[1] = 0;faultParam.faultClearingMode = kPWM_Automatic;

faultParam.faultLevel = true;

faultParam.enableCombinationalPath = false;

faultParam.recoverMode = kPWM_RecoverHalfAndFullCycle;PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_0, &faultParam);

PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_1, &faultParam);

PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_2, &faultParam);

PWM_SetupFaults(BOARD_PWM_BASEADDR, kPWM_Fault_3, &faultParam);

Thanks!