- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- MCUXpresso Training Hub

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

-

- Home

- :

- Product Forums

- :

- S32K

- :

- Re: hall sensor sector

hall sensor sector

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

hall sensor sector

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello Community,

I am using MCSPTE1AK144 EVB. I want to run a motor by using the 6 step commutation. Currently I am able to run the motor with hall sensor feedback. Now I am facing issues When the motor starts from the Sector 2.

At initial stage, If the rotor starts from sector 2 it is not going to next sector , I have to push the motor little bit to next sector then the motor starts rotating properly.

If the motor starts from any other sector , it is working properly. My doubt is why in sector 2 the rotor not able to move.

I am attaching my project please have a look and help me to solve this.

Thanks in advance,

Sarwath

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

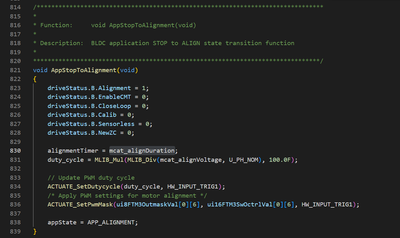

Alignment state is important for sensorless control of the BLDC Six-step.

Sensorless control with no position sensor requires to get rotor from unknown to known position.

Once you know where is your rotor position you can start-up the motor with maximum torque, because you can apply voltage vector/magnetic field perpendicular to rotor flux.

alignmentTimer is configurable parameter and it gives some time to rotor to be properly aligned with new required position.

BLDC control with Hall sensor doesn't need this alignment process. It can be bypassed.

Regards,

Marek

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello @marekmusak ,

Thanks for your response.

In MCSPTE1AK144_BLDC_6Step code both (sensor based/sensorless ) is using the alignmentTimer parameter. If I remove the alignmentTimer parameter (sensor based) motor is not rotating from particular sector (sector 2), then I added alignmentTimer. After adding it can able to rotate from all sector.

I attached my project in this same thread (without adding the alignmentTimer), Please have a look and let me know what I am doing wrong.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello @marekmusak ,

With the help of hall sensor feedback I got the actual rotor position.

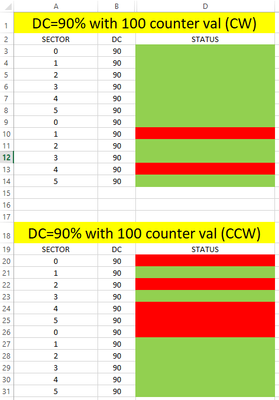

During start up, I gave duty cycle to 90 % once the motor start the duty cycle is controlled by the potentiometer. In few sector I am not getting the smooth start if I increase the POT value the motor is not rotating it is cogging then I deceased the POT value again I started increasing now it is rotating . what I understood is it taking time in few sector. I don't know the reason. I have attached my test result (CW and CCW). Please have a look and let me know your thoughts.

Note : STATUS green for good start and red for bad start.

BR,

Sarwath

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

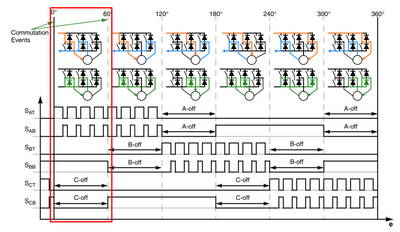

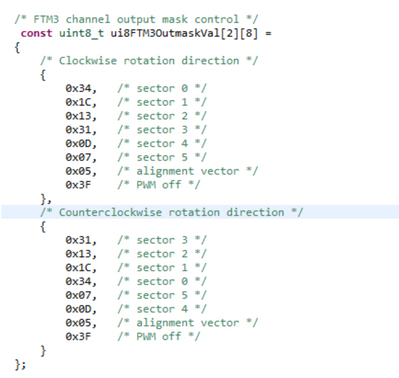

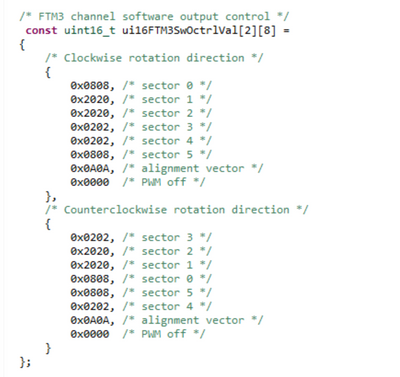

These two bit fields control OUTMASK and SWOCTRL of the Flextimer (FTM) in order to create complementary unipolar PWM (see AN12435 Figure 6).

Output Mask register (OUTMASK) provides a mask for corresponding FTM channel and Software Output Control register (SWOCTRL) actively force FTM channel to predefined value.

So for the 0 commutation sector we apply:

- Mask 0x34 in hex format and 0011 0100 in binar format.

- SW control 0x0808 in hex format and 1000 0000 1000 in binar format

So output of the FTM channels for 0 sector is:

- FTM3_CH0 generates PWM

- FTM3_CH1 generates PWM

- FTM3_CH2 is masked (OFF)

- FTM3_CH3 is actively controlled to high

- FTM3_CH4 is masked (OFF)

- FTM3_CH4 is masked (OFF)

See detailed description in application note AN12435.

Regards,

Marek

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello @marekmusak ,

Thanks for your explanation.

what is alignment vector? why it is required in BLDC motor control.

In MCSPTE1AK144_BLDC_6Step code (sensor based), after the alignment vector initialized there is delay (alignmentTimer) it is decreasing from 20,000 to 0. why this delay is required.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

I have asked kit owner to have a look at your query.

But meantime you can start with checking reference software, to find out where you did mistake.

Best regards,

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello @petervlna ,

Once the feedback from hall sensor the output mask control and software output control is set to generate the pwm. I want to knew the logic behind this i,e 0x34 and 0x0808 for sector 0. How it is predefined.

In sample code, after the alignment vector initialized there is delay (alignmentTimer) it is decreasing from 20,000 to 0. why this delay is required.

Thanks in advance,

Sarwath