- NXP Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- Vigiles

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Home

- :

- Product Forums

- :

- S12 / MagniV Microcontrollers

- :

- calibration error

calibration error

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

calibration error

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi,

I'm using the board MTRCKTSPNZVM128 with 3-phase Sensorless Dual-Shunt PMSM application -FOC driving.

It works normally with the motor NXP provided.

But It can't work when I using my motor .

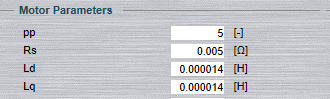

I changed the parameters as followed:

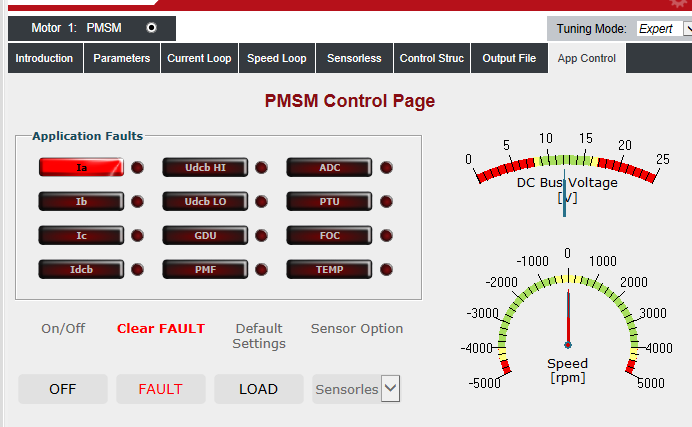

the fault is coming when the code runs to calibration state,please tell me why?

(state=Calib, Event=e_Calib,and then e_fault comes)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi,

can you please confirm that the application is going directly from the calib state and not even from a single call of align state?

If the app goes to the align state just for a few steps (thus for few 100 us periods only), the alignVoltage set too high can cause the current to go over the limit. If so, go to the Parameters tab of the MCAT and reduce the AlignVoltage value to zero. If the error occurs again, then we would start to find the problem.

You can step-by-step adjust the voltage to get the rotor in position and at the same time get some reasonable current.

Best regards,

Matej

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

I have the same error and when I reduce the AlignVoltage value to zero, the motor goes to the Align state then to the operating state, but the motor does not run.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

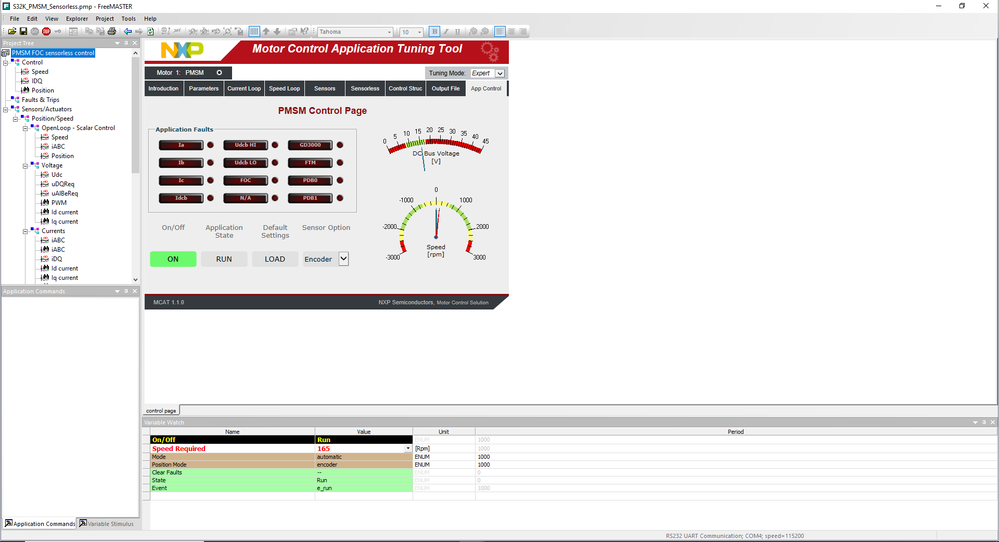

Have you tried to request speed form the "green" range? The open-loop start-up might have a problem with such small speed.

Thanks,

Matej

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Thanks for the advice but the nominal speed of my brushless motor is 280 rpm (it's a Brushless Gear Hub motor for e-bike). Is it acceptable to request a speed higher than its nominal speed?

Best regards,

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello,

if your motor is designed to a different speed range, then I would recommend to adopt the software to it. I believe some background can be found in this document: BLDC six-step control speed scaling using S12ZVM

For electric bike, I would recommend to use different to use torque (current) control structure instead of speed control - just like the throttle pedal in cars is used to command the torque instead of speed.

Even for cruise control, PI controller is not suitable due to the "integrator" included, which can cause overshoots in control and some other difficulties. But I'm not sure any kind of cruise control is useful for electric bikes.

Best regards,

Matej