- Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- Wireless ConnectivityWireless Connectivity

- RFID / NFCRFID / NFC

- Advanced AnalogAdvanced Analog

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

- S32M

- S32Z/E

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

- Generative AI & LLMs

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

- Cloud Lab Forums

-

- Knowledge Bases

- ARM Microcontrollers

- i.MX Processors

- Identification and Security

- Model-Based Design Toolbox (MBDT)

- QorIQ Processing Platforms

- S32 Automotive Processing Platform

- Wireless Connectivity

- CodeWarrior

- MCUXpresso Suite of Software and Tools

- MQX Software Solutions

- RFID / NFC

- Advanced Analog

-

- NXP Tech Blogs

- Home

- :

- General Purpose Microcontrollers

- :

- Kinetis Microcontrollers

- :

- How to program a Servo motor in KL25Z

How to program a Servo motor in KL25Z

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to program a Servo motor in KL25Z

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I must program a Servomotor in freescale, I have this program but the servo can´t power on.

I need to make the servo go from 0° to 180°

Please help me!

Could you please explain me each part of the correct form to program a servo motor.

#include "MKL25Z4.h"

int main (void){

SIM->SCGC5 |= 0x1000; /* enable clock to Port D */

PORTD->PCR[2] = 0x0400; /* PTD1 used by TPM0 PIN DEL PRIMER SERVOMOTOR */

SIM->SCGC6 |= 0x01000000; /* enable clock to TPM0 */

SIM->SOPT2 |= 0x01000000; /* use MCGFLLCLK as timer counter clock */

while(1){

TPM0->SC = 0; /* disable timer */

TPM0->CONTROLS[3].CnSC = 0x20 | 0x08; /* edge-aligned, pulse high */

TPM0->MOD = 43702; /* Set up modulo register for 60 kHz */

TPM0->CONTROLS[3].CnV = 437; /* Set up channel value for 1% dutycycle */

TPM0->SC = 0x0C; /* enable TPM0 with prescaler /16 */

delayms(20);

}}

void delayms(int n)

{int i;

int j;

for(i=0; i < n; i++)

for (j=0; j < 7000; j++){} }

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Gerardo,

in addition to the reply from Robin, you might have a read at Tutorial: Arduino Motor/Stepper/Servo Shield – Part 1: Servos | MCU on Eclipse .

I hope this helps,

Erich

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Gerardo,

Sorry for the late reply!

Please read 'Servo control interface in detail' and 'Introduction to Servomotor Programming' first.

The typical pulse period is around 20 ms, which corresponds to a frequency of 50 Hz. (But you have configure frequency of 60kHz which may too high.)

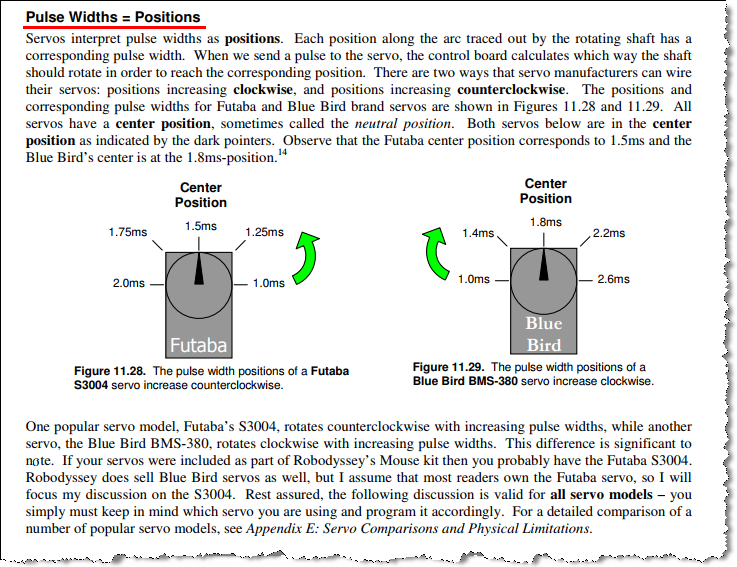

The pulse width is generally the most important part of the interface, and that is what we intentionally vary to change the command to the servo. The general idea is simple: a pulse width of 1.5 ms is what we consider “neutral”; increasing the pulse width will make the servo go one way, and decreasing the pulse width will make the servo go the other way.(But you have configure 1% dutycycle which may too small.)

I am not sure what type Servo Motor are you using. For different Servo Motor, the Pulse Width of Center Position maybe different.

Best Regards,

Robin

-----------------------------------------------------------------------------------------------------------------------

Note: If this post answers your question, please click the Correct Answer button. Thank you!

-----------------------------------------------------------------------------------------------------------------------