- NXP Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- Vigiles

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

-

- Home

- :

- Product Forums

- :

- Sensors

- :

- MMA8451 wrong sensor data over time - damaged chip?

MMA8451 wrong sensor data over time - damaged chip?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

MMA8451 wrong sensor data over time - damaged chip?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi all

We at my company, has a very strange issue regarding til MMA8451. We are experincing that our accelerometers data can be suddenly wrong over time.

We have approximately 250 devices out, running in the field, and we have about 10 devices which got this problem. What happens is that the sensor data:

- Suddenly has a completely wrong offset (out of the min/max values, that the MMA should even be capable of).

- Or has it's z-axis locked in a "fixed" value or fluctuating.

We see that a mechanical bump of the PCB/sensor can make it suddenly work again. That makes us think that the MMA chip has been damaged.

If we take a brand new MMA and solder onto a PCB which had the problem ealier, no problems exists. So it's happening over time. And when it has happend, it can recover or come back to normal again.

We do of course have a lot of software, checking that all communication is alright on the I2C etc. We interface with a STM32 microcontroller. When the problem occurs, all power offs, resetting the chip etc, has no influence of the wrong data.

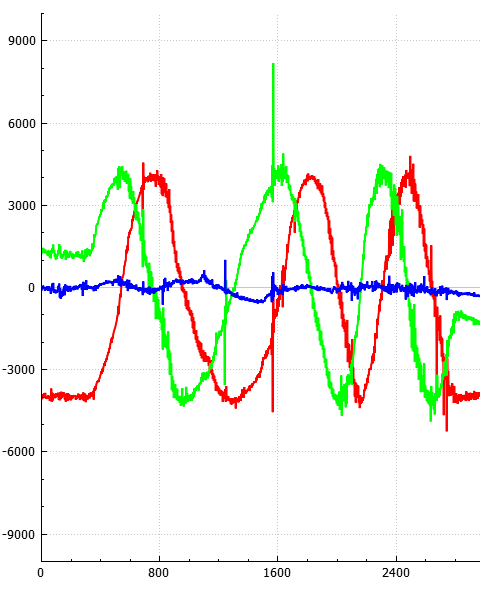

Here I have some visualizations of how the data looks. First an all normal functioning MMA measurement: (x-axis = red, y-axis = green and z-axis = blue). All measurement are done with the device fixed horizontal in the z direction, and then turned around the z-axis.

The x axis of this graph is samples (100 hz sample rate). The y axis is the raw sensor value.

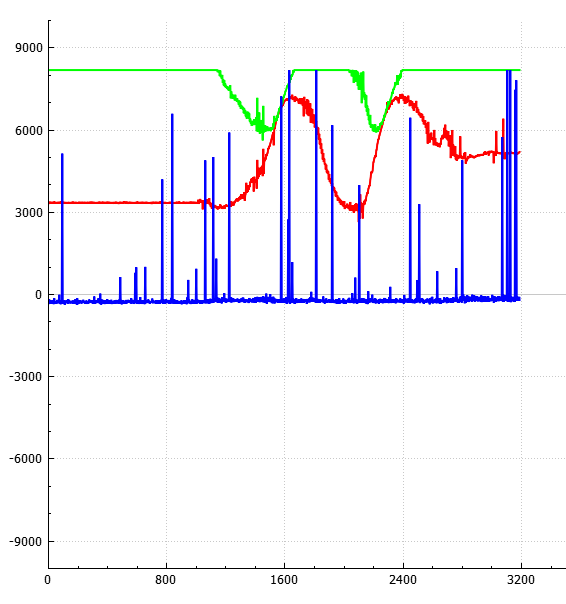

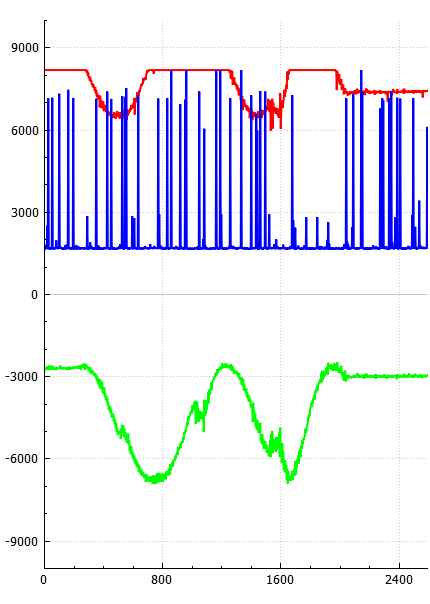

The following pictures shows malfunctioning MMA measurements:

And another:

As you see, the sensor works in some sense, as the x and y axis changes. But has an unrealistic offset. If we hit the device mechanically, the axis happens to be normal afterwards.

The z-axis can act like this, just fluctuating, or it can be locked in either 8192 (max) or -8191 (min).

We have done various ESD tests to debunk that hypothesis. But we are very confused.

We hope that NXP or other people, have some knowledge about this issue, or have heard about this before?

Thanks in advance, people.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hi Mikkel,

Could you please elaborate on how the MMA8451Q is being used in your application?

It sounds to me partially like a quality problem known as Z-axis stiction failure. Devices with this failure usually have a positive (0x7FFC) or negative (0x8000) railed output.

In fact, sticking can arise during manufacturing or in the use of the device. As you can see in the the PCN14989 and PCN15484, there have been made some design/test improvements to eliminate this failure. In‐use sticking may occur after a high acceleration event causes its movable elements to contact its fixed surfaces. Another mechanical shock usually bring them back to work properly.

Customers that experience an issue similar to this can contact our quality team and customer service team. The NXP Quality team will enter the information into the NXP CQC system to route to the correct quality team and business line contacts for support.

As for the offset on the X (red) and Y-axis (green), I have not heard or seen similar problems so far. I would recommend to send back the affected pieces to perform a quality analysis. Our standard procedure for this is to submit a CQI request for failed parts through your purchasing party.

Best regards,

Tomas