- NXP Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- Vigiles

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

-

- Home

- :

- Product Forums

- :

- Other NXP Products

- :

- BT136 bad parts / wrenched arms

BT136 bad parts / wrenched arms

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

BT136 bad parts / wrenched arms

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Main: I have big number of bad parts - BT136. (every 6-th part approx.)

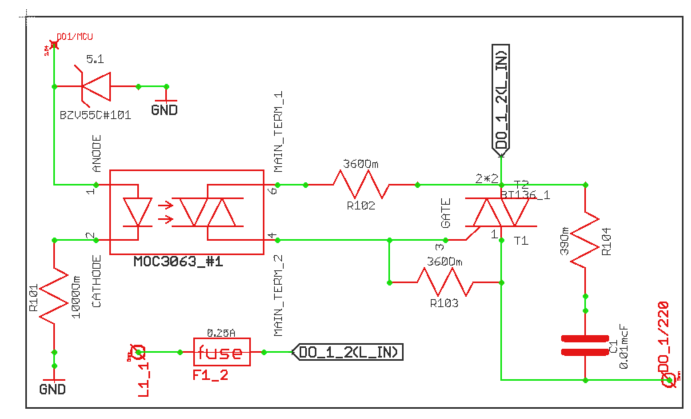

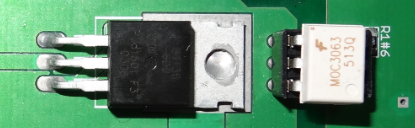

In my PLC design I'm using BT136 traics in package TO-220AB.

I'm use it like key in conjunction with MOC3063:

In most cases everything fine, but sometimes it doesn't close. I have 220V on terminals and gate even when I remove MOC3036 and even after I desolder C1 capacitor.

I look on two opportunities:

1. I'm damaging this devices while soldering.

2. Local supplier - company Chip'n'Dip is supplied my counterfeit parts (We already have such experience).

For the first:

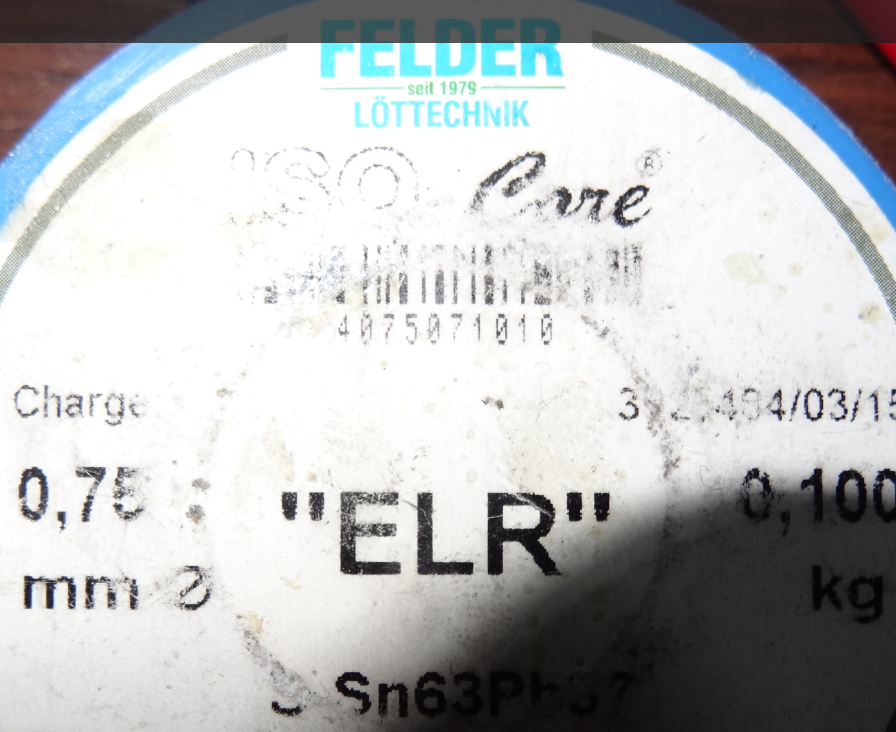

I mounting BT136 in plain of PCB. In this case I drown hole in mounting base by solder: Sn63Pb37 (180...190 deg.C) and bend and solder all three legs through holes:

Like flux I'm using resinfilled isopropyl:

Solder station temperature - 370deg.C (I'm quick solderer). In the same manner I solder dsPIC30f6014 or max3232 - and all parts work good. But with BT136 i have many spoiled keys in result.

Today I re-solder 4 of 8 parts on one of my PLCs.

Could you provide some info about soldering temperature for this device. Or say what I'm doing wrong.