- NXP Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- Vigiles

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

-

- Home

- :

- Product Forums

- :

- S32K Knowledge Base

- :

- Automotive Electrical E-compressor Aircon RDB based on S32K142 Released

Automotive Electrical E-compressor Aircon RDB based on S32K142 Released

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Automotive Electrical E-compressor Aircon RDB based on S32K142 Released

Automotive Electrical E-compressor Aircon RDB based on S32K142 Released

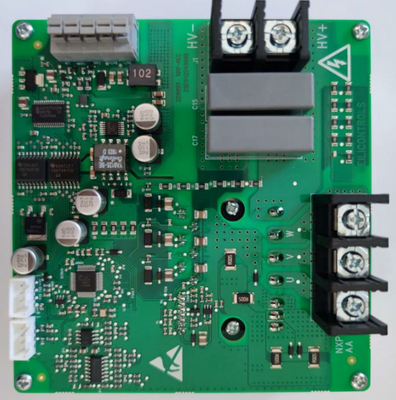

EV/HEV is the mega trend and NXP focused area. E-Compressor controller is a key and additional component of EV/HEV vs. traditional vehicle. While S32K14x is the perfect product for mainstream E-compressor application. To accelerate customer develop period in automotive E-compressor application, we develop the S32K142-ECC RDB. Actually, S32K142-ECC is not only suitable for E-compressor, but also can be used in other high voltage PMSM/BLDC application in automotive industry.

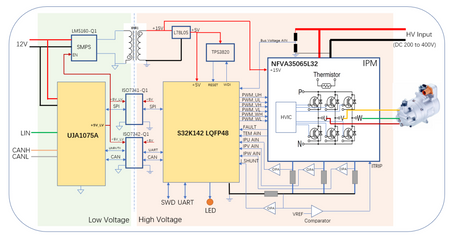

This RDB (Reference Design Board) hardware is based on NXP S32K142 high-performance automotive-grade MCU and UJA1075A SBC (system basic chip) provides the following features:

◼ Support high voltage up to 400V and power range up to 3.7kW BLDC/PMSM applications.

◼ Support high voltage isolated 12V power supply, which for SBC, IPM and MCU power supply.

◼ Hardware support 3 types of current sampling solutions: single shunt, dual shunts and triple shunts; software support dual shunts in V1.0.

◼ Support multiple diagnose and protection covering UV, OV, OT, OC, Short, Stall Detection, etc.;

◼ Support speed/control commands from CAN/LIN/FreeMASTER;

◼ Support external watch dog for safety.

the RDB hardware system block diagram is as below:

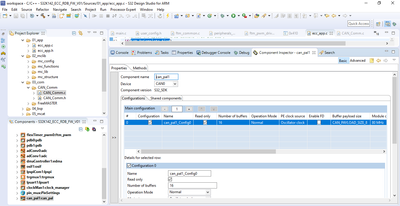

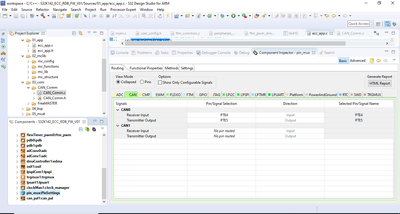

The software package of S32K142-ECC RDB is available to enable user to evaluate the S32K142 based high voltage e-compressor motor control performance with out-of-box and build their own e-compressor motor control product prototype as a general high voltage motor control hardware platform.

The software package has the following features:

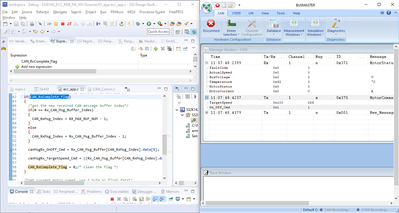

◼ Support e-compressor control by FreeMASTER CAN/UART;

◼ Support e-compressor speed control and state feedback by CAN DBC file;

◼ Implemented advanced motor control algorithm, including low speed torque compensation, MTPA, 2-stage current alignment and enhanced ATO to make sure the motor robust start up and high efficiency;

◼ Support rich motor control diagnostic and protection: OV, UV, OC, OT, stall and phase loss and so on;

◼ Provide S32DS IDE and IAR for ARM IDE projects, support U-Multilink and J-LINK debugger;

We have several S32K142-ECC RDB in stock, if you have the project and need the RDB for evaluation, please contact your local NXP or NXP dist FAE, Sales and Marketing.

For technique support, contact raymond.tang@nxp.com

thanks,

Best regards,

Raymond

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content