- NXP Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- Vigiles

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

-

- Home

- :

- Model-Based Design Toolbox (MBDT)

- :

- Model-Based Design Toolbox (MBDT)

- :

- Unreliable PWM synchronized ADC acquisition on S32K

Unreliable PWM synchronized ADC acquisition on S32K

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

I am having issues implementing an FOC closed loop control for a PMSM, due to unexpected behavior of the ADC acquisition. This is my first project with S32K and the Model Based Design Toolbox, so help in solving or at least better understanding the issue would be greatly appreciated!

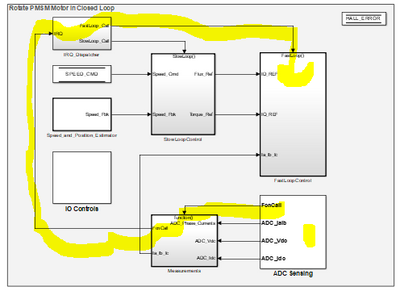

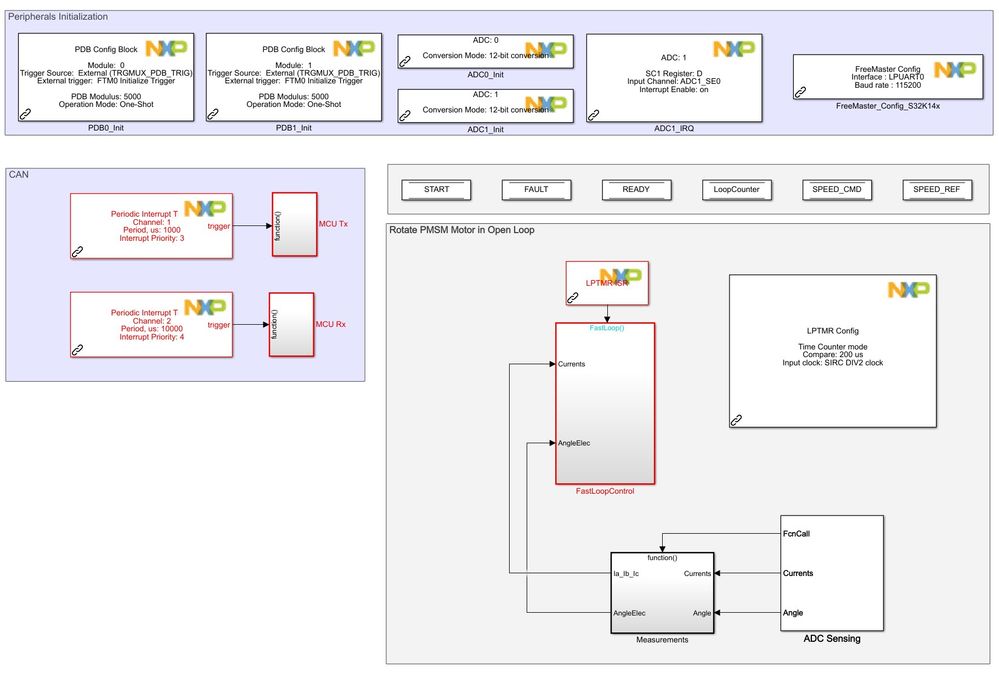

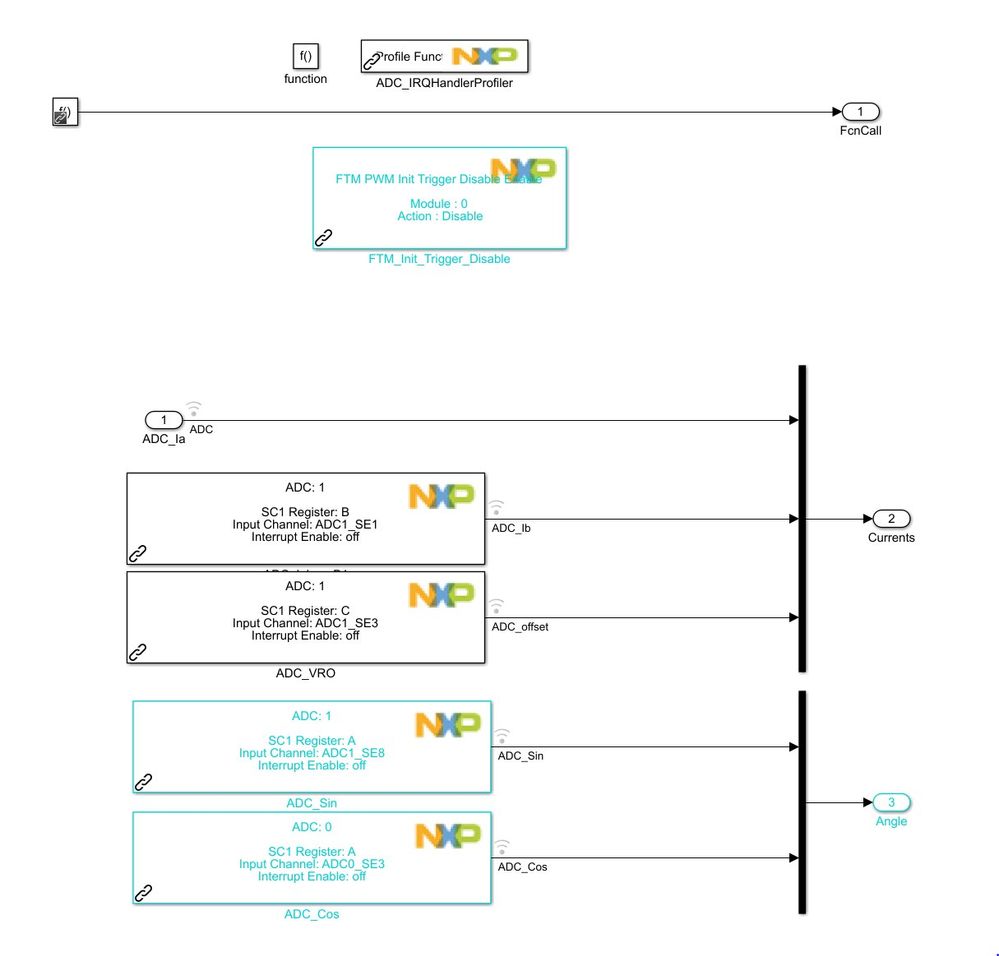

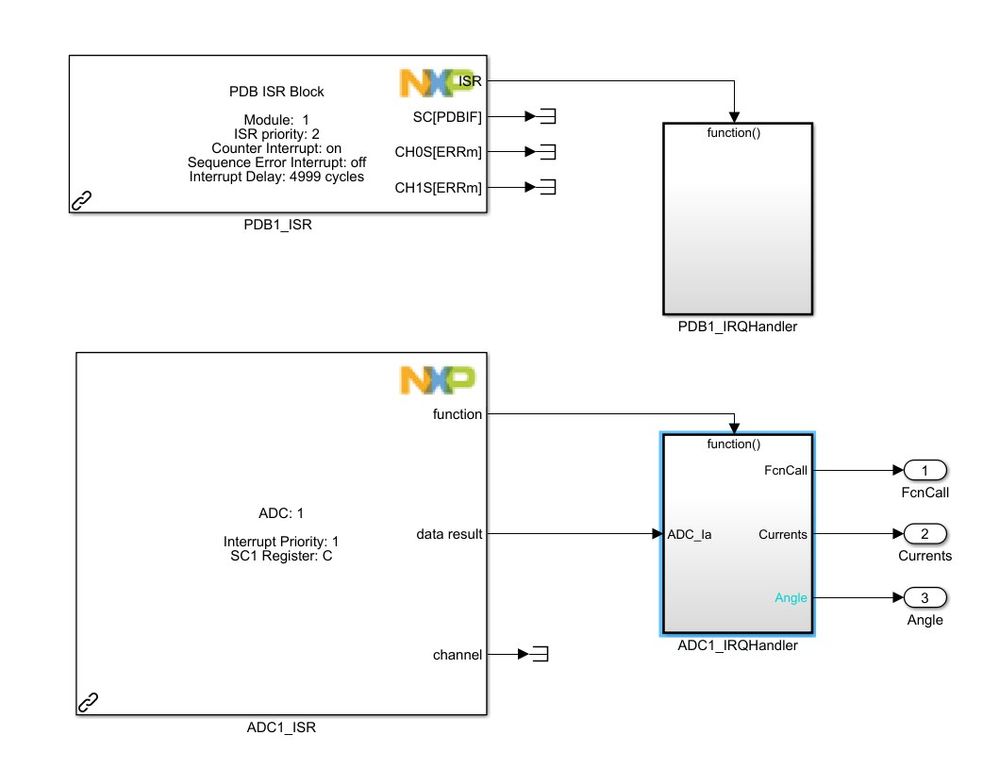

I started from the example "PMSM_ClosedLoop_s32k144" provided in the Model Based Design Toolbox for simulink, and I adjusted the inputs basing on my specific setup, by modifying the "ADC Sensing" block, the "Measurements" block and the "Peripherals Initialization" block, as shown in the following screenshots. For the control loop I used a dedicated 5 kHz LPTMR timer. In addition I'm using a CAN interface for debugging.

The scheme seems to work, but is very unreliable: after a seemingly random time, ranging from some seconds up to few minutes, all the inputs seem to freeze (the ADC interrupt stops working?), while the control loop keep working as expected, as confirmed by the CAN signals. The event seems to manifest quicker if the motor is spinning faster and when I am sending CAN messages to the board. It also seem to be related to changes on the FastLoop block, but despite countless attempts I haven't been able to identify any clear correlation. Sometimes very small changes in the diagram structure cause the ADC acquisition to not even start. I tried to tweak all parameters, from PDB pre triggers to ADC registers and interrupt priority, without success. It is driving me crazy.

Do you have any suggestion on how to fix this problem? Or at least any reference that could help me to identify the issue?

Thank you very much!

Solved! Go to Solution.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello @dennymopper

My guess is that the issue is related to the synchronization between FTM-PDB-ADC timing. You see, in the initial model, the PWM frequency is 20kHz. At each two PWM cycles, the PDB triggers the ADC to perform current measurements. Each complete conversion triggers the control loop, calling each time the FastLoop and 10 times slower the SlowLoop. So the control loop is basically performed at 10kHz

Now, the FTM has an initialization trigger that is sent to PDB each time the FlexTimer's MOD value is 0. The way in which the frequency is halved is by disabling the FlexTimer Initialization trigger for the n+1 PWM cycle when the ADC conversion complete interrupt is triggered in the nth PWM cycle. The PDB interrupt is delayed with 5000 cycles and then the FTM Initialization trigger is enabled again.

The way you want to achieve the 5kHz control loop is by using another timer that is not in sync with this process, while the method above is synchronous, without existing the possibility to let's say disable the triggers forever.

One of the easiest solution would be to delete the FTM init trigger disable enable blocks from inside the PDB1_IRQHandler and ADC1_IRQHanlder to basically perform ADC conversions every PWM cycles, but your control loop every 5kHz. I would also move the measurements block in the control loop. Also, consider using the Lptmr Start Stop Counter block to start the LPTMR counter at the same time when you start the FTM signals generation.

Hope this helps,

Marius

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Hello @dennymopper

My guess is that the issue is related to the synchronization between FTM-PDB-ADC timing. You see, in the initial model, the PWM frequency is 20kHz. At each two PWM cycles, the PDB triggers the ADC to perform current measurements. Each complete conversion triggers the control loop, calling each time the FastLoop and 10 times slower the SlowLoop. So the control loop is basically performed at 10kHz

Now, the FTM has an initialization trigger that is sent to PDB each time the FlexTimer's MOD value is 0. The way in which the frequency is halved is by disabling the FlexTimer Initialization trigger for the n+1 PWM cycle when the ADC conversion complete interrupt is triggered in the nth PWM cycle. The PDB interrupt is delayed with 5000 cycles and then the FTM Initialization trigger is enabled again.

The way you want to achieve the 5kHz control loop is by using another timer that is not in sync with this process, while the method above is synchronous, without existing the possibility to let's say disable the triggers forever.

One of the easiest solution would be to delete the FTM init trigger disable enable blocks from inside the PDB1_IRQHandler and ADC1_IRQHanlder to basically perform ADC conversions every PWM cycles, but your control loop every 5kHz. I would also move the measurements block in the control loop. Also, consider using the Lptmr Start Stop Counter block to start the LPTMR counter at the same time when you start the FTM signals generation.

Hope this helps,

Marius

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Restoring the dependency between the PDB trigger and the control loop fixed the issue. Now everything works as expected. Thank you very much for your help and for the illuminating explanation!