- NXP Forums

- Product Forums

- General Purpose MicrocontrollersGeneral Purpose Microcontrollers

- i.MX Forumsi.MX Forums

- QorIQ Processing PlatformsQorIQ Processing Platforms

- Identification and SecurityIdentification and Security

- Power ManagementPower Management

- MCX Microcontrollers

- S32G

- S32K

- S32V

- MPC5xxx

- Other NXP Products

- Wireless Connectivity

- S12 / MagniV Microcontrollers

- Powertrain and Electrification Analog Drivers

- Sensors

- Vybrid Processors

- Digital Signal Controllers

- 8-bit Microcontrollers

- ColdFire/68K Microcontrollers and Processors

- PowerQUICC Processors

- OSBDM and TBDML

-

- Solution Forums

- Software Forums

- MCUXpresso Software and ToolsMCUXpresso Software and Tools

- CodeWarriorCodeWarrior

- MQX Software SolutionsMQX Software Solutions

- Model-Based Design Toolbox (MBDT)Model-Based Design Toolbox (MBDT)

- FreeMASTER

- eIQ Machine Learning Software

- Embedded Software and Tools Clinic

- S32 SDK

- S32 Design Studio

- Vigiles

- GUI Guider

- Zephyr Project

- Voice Technology

- Application Software Packs

- Secure Provisioning SDK (SPSDK)

- Processor Expert Software

-

- Topics

- Mobile Robotics - Drones and RoversMobile Robotics - Drones and Rovers

- NXP Training ContentNXP Training Content

- University ProgramsUniversity Programs

- Rapid IoT

- NXP Designs

- SafeAssure-Community

- OSS Security & Maintenance

- Using Our Community

-

-

- Home

- :

- Topics

- :

- NXP Designs Knowledge Base

- :

- Machine Vision Demo

Machine Vision Demo

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Machine Vision Demo

Machine Vision Demo

Demo Owner: David Chung

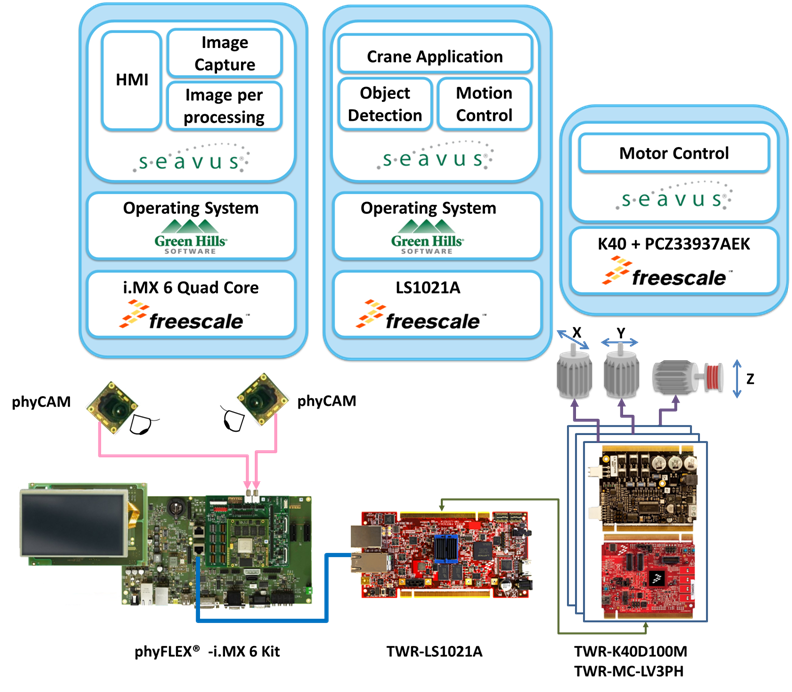

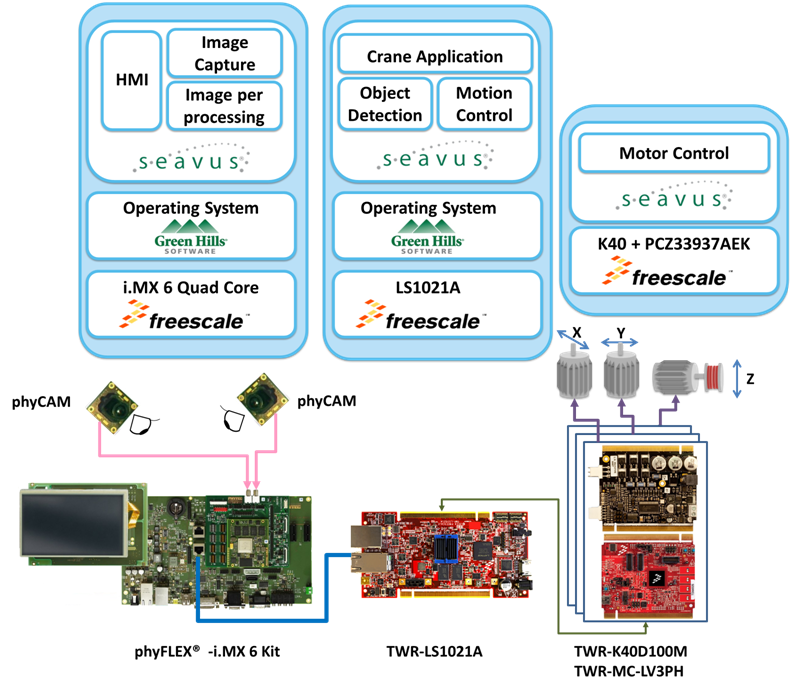

Intended to demonstrate how one can leverage NXP technology to safely transport loads in a range of settings from a shipyard to an assembly line.

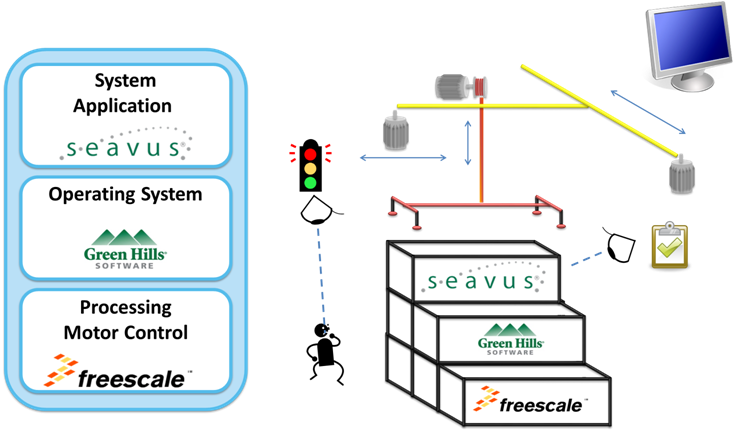

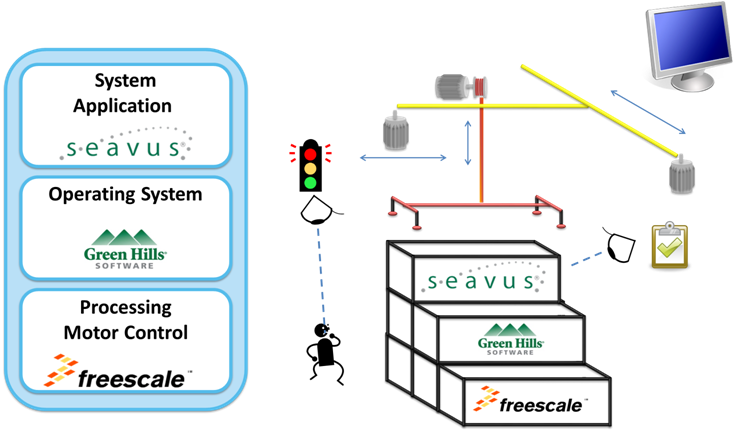

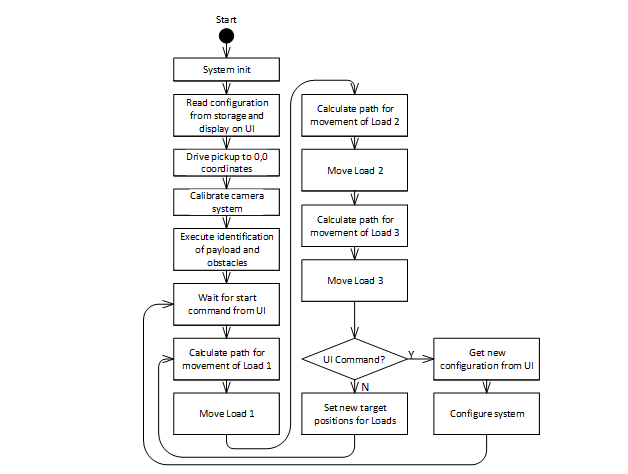

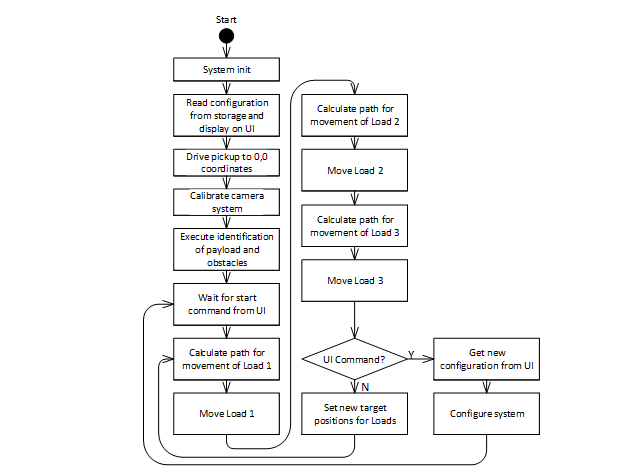

Demo runs a Seavus developed application that pre-calculates a path based on environmental input given by the QorIQ LS1021A. It then moves the load according to that path, adjusting for unforeseen hazards such as people who move in the way during transport. It ensures that the landing area is clear before dropping the load.

Demo is entire self-contained.

Features

QorIQ LS1021A

- FPU for precise mathematical computation

- IEEE 1588 Precision Time Protocol to sync clocks within system

- WiFi connectivity to Human-Machine Interface

- SEC 5.5 crypto accelerator for maximum security

- Dual core for redundancy

i.MX6

- Specialized imaging processor

- Used as camera interface to facilitate trajectory calculation

- General purpose low power MCU

- Utilized to control the crane's stepper motor

Green Hills INTEGRITY RTOS

- Certified EAL6+ High Robustness by NSA

- Separates critical and non-critical tasks

Seavus Crane Application

- Efficient algorithm for trajectory calculation and load transport

Block Diagrams

Organizational Structure

Algorithm Diagram

Function Allocation

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Cool demo David. I would really like to see this demo presented in the context of a DIY'er pick-and-place type of machine. Seems like you have most of the hardware already for it.

- Mark as Read

- Mark as New

- Bookmark

- Permalink

- Report Inappropriate Content

Hi John,

Thank you for your interest. The demo is currently being remodeled to include i.MX and Kinetis. John Ralston is the expert to contact about the demo. Hope this helps.

-David